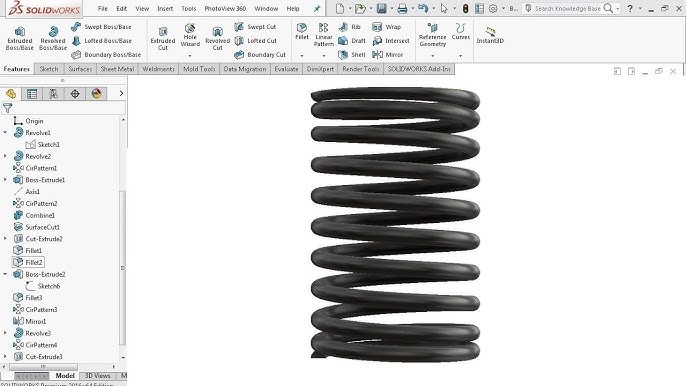

Definition: A guide to designing compression springs providing the user with several compression spring formulas and calculations required to achieve a functional compression spring design.

Are you in need of assistance on your compression spring design? No worries because at Hengsheng Spring, we’ve got you covered with this exceptional compression spring design guide. And here you will be instructed to make all of the decisions required to design a compression spring; in addition to material type and dimensions to your spring’s force and elasticity.

1.) Dimensions and Material

As shown on our spring calculator, Spring Creator, you must first set your compression spring’s physical dimensions and specifications. These don’t only include your compression spring’s measurements but also the end types and material types.

First, measure your compression spring’s surroundings to ensure that the dimensions you decide upon will not affect the spring when installed. If it is going over a shaft or hole, you must be vigilant about the inner and outer diameters.

Futhermore, always ensure you have some clearance between your spring’s coil diameters, and the walls of the hole/shaft or other mounting pieces that may intervene with the spring’s deflection. Thus avoid damage caused by friction or impact on the coils.

Lastly, the spring should be pre-loaded, so make sure that the free length of your spring is a bit longer than the distance from the base where the spring will be standing to the object that’ll be applying force. You can find the compression spring design formulas to calculate its physical dimensions and how to choose a material type below.

End types

There are several types of compression spring ends types. In fact the most popular ends are closed and squared ends. Whereas the other end types provided on our compression spring calculator are closed, and grounds ends, double closed ends, and open ends. Changing the end types will affect your spring instability and even force. Because changing the end type and keeping the active coils the same will affect the total coil count or solid height. As a result, affecting the coil count could result in force changes as specified on the later provided force chart.

Material Type

Choosing the material type of your compression spring is very important in the compression spring design process. In fact, choosing the wrong material for your spring can either cause your spring not to work in the required environment or unnecessary costs. However, unnecessary costs are bound to happen when selecting a material type if you picked an exotic material type, while you could’ve used a more common wire type such as Music Wire ASTM A228 or Stainless Steel 302 A313. In situation where your spring is not working can be caused by not considering your spring’s environment when it comes to corrosion, high temperatures, or magnetic fields.

Formulas

Outer Diameter: You can calculate the diameter of your compression ring by adding two wire width to the inner diameter.

Inner Diameter + 2 Wire Diameters = Outer Diameter

ID + 2 WD = OD

Inner Diameter: You can also calculate the compression spring’s inner diameter by doing the opposite, subtracting two wire diameters from the outer diameter.

Outer Diameter – 2 Wire Diameters = Inner Diameter

OD – 2 WD = ID

2.) Force and Elasticity

Its spring rate or constant defines your compression spring’s force. This specification is expressed in load per distance traveled (lb/in or N/mm), which means that your compression spring’s distance traveled will depend on the gear you apply and vice versa. The amount of load at a specific distance traveled is your spring’s working load. Knowing these values will help you determine the spring rate you must have for your spring to function as planned. We provide the formula used on our calculator to calculate the compression spring rate to the right. As you can see, the spring’s physical dimensions and material type have much to do with how strong your spring will be.

Maximum Travel and True Maximum Travel

Knowing your load and travel doesn’t necessarily mean you’re going to be able to achieve it, however. Springs have an elastic limit that only allows you to travel a certain distance, thus limiting your load. There are two different values for travel and load limitations. There is True Maximum Travel and Maximum Travel Considering Solid Height, as well as True Maximum Load and True Maximum Load Considering Solid Height. These are both related to each other since the distance your spring travels is proportional to its load. Authentic Maximum Travel is a possible amount of travel. This measurement means you can get that much travel if you make your compression spring’s free length longer.

On the other hand, the Maximum Travel Considering Solid Height is the amount of travel you’ll get out of the spring design you have now. If the True Max Travel is higher than the Maximum Travel Considering Solid Height, you can extend the free length, and your compression spring can also travel down to solid height. If they are the same, it means your spring has reached its limit, and you cannot extend its free length because you’re already getting all of the travel the spring can achieve with its current dimensions. That would be your compression spring’s maximum compression. While the same goes for the True Maximum Load and Maximum Load Considering Solid Height. We also provided the formulas below to calculate your required rate and working loads.

Compression Spring Formula Guides

In order to calculate the amount rate on a compression spring design based on physical dimensions, including material type. And use the formula provided below:

k = Gd^4 / 8D^3N

Explanation of Symbols:

- d = Wire Diameter

- D = Mean Diameter

- N = Active Coils

- G = Shear Modulus of Material

- K = Spring Constant

G-Value for Common Spring Materials

- Music Wire = 11.5 x 10^6

- Stainless Steel = 11.2 x 10^6

- Phosphor Bronze = 5.9 x 10^6

- Monel = 9.6 x 10^6

- Inconel = 11.5 x 10^6

- Copper = 6.5 x 10^6

- Beryllium Copper = 6.9 x 10^6

Calculate spring rate

To calculate your compression spring’s rate (k) you must divide your spring’s load (L) by the distance traveled (T).

Rate = Load ÷ Travel

k = L ÷ T

Calculate working loads

To calculate your compression spring’s load (L) at a certain distance traveled, you must multiply the spring rate (k) by that distance traveled (T).

Load = Rate x Travel

L = kT

Calculate distance traveled

To calculate the distance traveled (T) under a specific load, you must divide the compression spring’s load (L) by the spring rate (k).

Travel = Load ÷ Rate

T = L ÷ k

I want to to thank you for this wonderful read!! I absolutely loved every little bit of it. I have you saved as a favorite to look at new stuff you postÖ

The content is very good, I will continue to pay attention to

Thank you for your support of Hengsheng Spring, we are looking forward to your comments and suggestions!