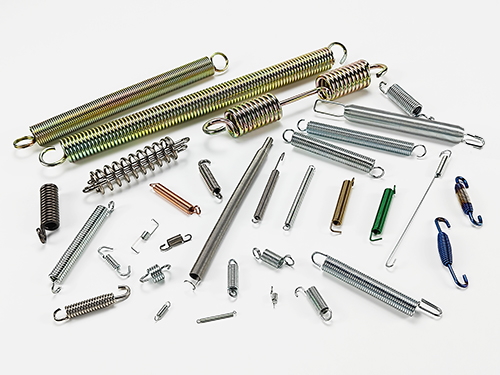

Custom Spiral Spring Manufacturer

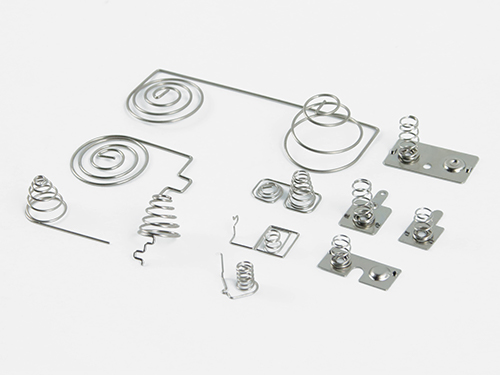

As a custom spiral spring manufacturer with 21 years of experience, HengSheng Spring can produce a wide variety of spiral spring sizes, shapes, materials, and designs, as well as clock springs, constant force springs, and power springs. From precision small flat spiral spring to big heavy duty spiral torsion spring, we can provide high quality solutions.

Please offer us your spiral spring specifications, we will send you a quote very soon.

Custom Flat Spiral Springs Specifications

We listed some of the most common custom spiral springs manufacturer specifications, such as sizes, shapes, and materials. HengSheng Spring also provides fully customized production of all kinds of flat spiral springs.

- Whether a bulk order or a sample, we offer a customized service.

- ISO9001 and IATF16949 certificated custom spiral spring manufacturer.

- We offer competitive prices based on our experienced engineers and advanced equipment.

- Work with our engineers to optimize your spring designs and lower costs, our team can provide expert design assistance on any order.

Flat Wire Size

- 0.01~1 mm in thickness

- up to 10 cm in width

- flat wire

Common Spring Materials

- carbon steel

- stainless steel

- stainless alloy

- titanium

- plating

- black oxide

- and more

Spiral Spring Types

- spiral torsion spring

- constant force spring

- power springs

- clock springs

- rewind spring

- and more

If you’re creating a spring, reach out to our engineering team for assistance. We’ll ensure you’re connected with the appropriate expert who can provide the support you need.

21 Years

Spring Manufacturer Experience

5000+㎡

Production Workshop

20+

Experienced Engineers

Unlimited

Custom Capabilities

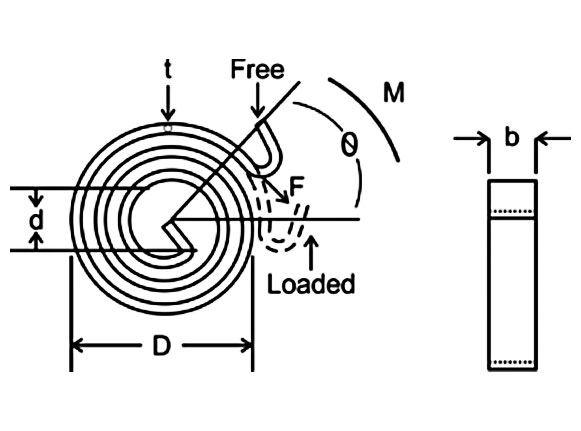

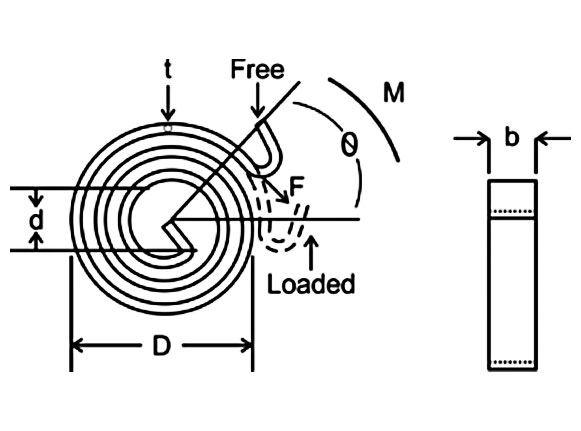

Dimensions Measurement

- t (thickness): measure the thickness of the flat wire.

- b (width): measure the width of the flat wire.

- D (O.D): measure the outside diameter of the coil.

- d (I.D): measure the inside diameter of the coil.

- N (number of coils): check the number of coils the spiral spring have.

Common Materials Used for Spiral Torsion Spring

Flat spiral springs require careful consideration of several factors including strength, elasticity, wear resistance, and corrosion resistance. Here are some commonly used materials for spiral springs:

Carbon Steel:

-

- Advantages: Cost-effective, good strength and elasticity.

- Applications: Suitable for general industrial use and low-cost applications.

- Common Types: High carbon steel, medium carbon steel.

Stainless Steel:

-

-

- Advantages: Excellent corrosion resistance, suitable for humid or corrosive environments.

- Applications: Widely used in medical devices, food processing machinery, and marine equipment.

- Common Types: 301 stainless steel, 304 stainless steel, Carbon steel.

-

Alloy Steel:

- Advantages: High strength and wear resistance, suitable for high-stress and high-fatigue applications.

- Applications: Typically used in aerospace, automotive, and heavy machinery industries.

- Common Types: Silicon manganese steel, chromium-vanadium steel.

Nickel Alloys:

- Advantages: Excellent performance in high-temperature and corrosive environments.

- Applications: Used in high-temperature environments such as jet engines and nuclear power plant equipment.

- Common Types: Inconel series, Monel series.

Bronze and Brass:

- Advantages: Good corrosion resistance and electrical conductivity, with decent elasticity.

- Applications: Often used in electrical and electronic devices, and marine environments.

- Common Types: Phosphor bronze, beryllium copper.

Verified Custom Spiral Spring Manufacturer

As one of the largest custom spiral spring manufacturers in China, we take pride in our ISO9001, IATF16949, and SGS certifications, which testify to our unwavering commitment to quality and excellence.

We provide a comprehensive suite of services, including the production of custom spiral springs of all varieties including spiral torsion springs, constant force springs, clock springs, and power springs. Supported by state-of-the-art CNC spiral coiling equipment. We offer prototyping and tooling assistance, ensuring that we can support you at every stage of the design and production process.

We’re dedicated to surpassing your expectations, delivering compression springs that are tailor-made to your exact specifications.

Contact Us

Need help with pricing, technical queries about springs, or any other product-related assistance?

Our team is equipped with sales professionals, design engineers, and manufacturing experts ready to address your needs. We’ll make sure you’re connected with the person most qualified to help.