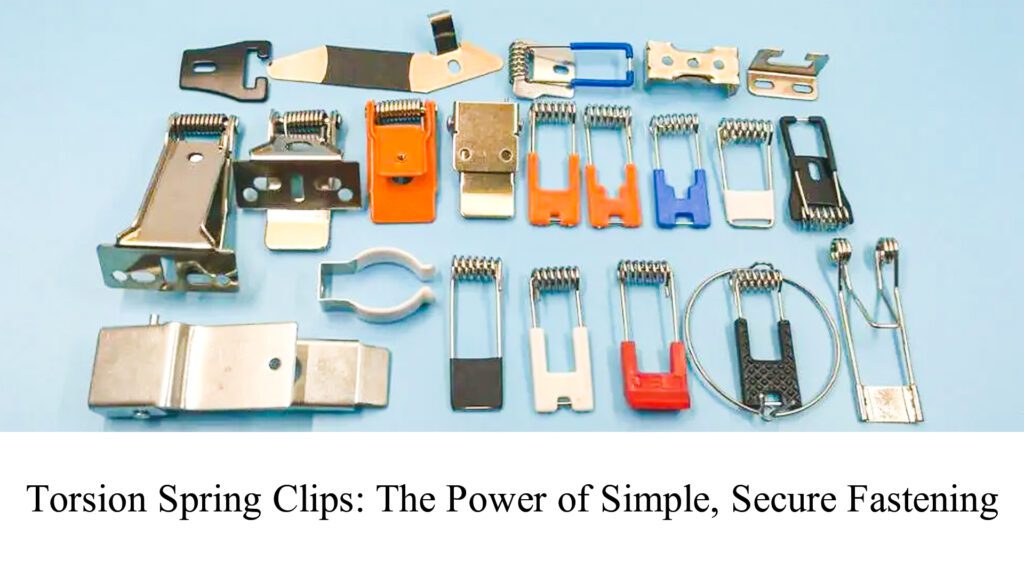

A Torsion Spring Clip combines a traditional torsion spring with a clip design to offer an efficient and secure fastening solution. By leveraging the power of rotational energy, these clips hold components in place with ease, making them an essential tool in various industries. In this article, we will explore the unique features, applications, and advantages of torsion spring clips.

What is a Torsion Spring Clip?

Torsion spring clips consist of a coiled spring that stores rotational energy when twisted. As force is applied, the spring twists, providing tension that securely holds parts together. Once the force is removed, the spring returns to its original position, ensuring that the clip stays in place. This mechanism allows for efficient, quick attachment and detachment, making it perfect for various uses.

Where Are Torsion Spring Clips Used?

- Automotive Industry: In automotive manufacturing, torsion spring clips are widely used to secure panels, doors, and trim components. These clips save time by providing a quick fastening solution, which helps streamline the assembly process. Moreover, they reduce the need for tools, making assembly easier and more efficient.

- Electronics: In electronics, these clips are essential for holding circuit boards and wires in place. Torsion spring clips enable secure attachment in small, confined spaces, where traditional fasteners may be too bulky. Their compact design and ease of use make them ideal for electronics.

- Furniture and Household Items: Torsion spring clips are also found in furniture such as folding tables and chairs. They hold adjustable parts firmly, providing flexibility and stability. You’ll find them in household items like clipboards and toys as well, where ease of use and durability are required.

- Industrial Applications: In industrial settings, torsion spring clips play a crucial role in securing machinery and equipment parts. These clips help prevent parts from shifting or vibrating, which ensures the safe and efficient operation of heavy-duty machines.

- Consumer Products: Everyday consumer products like hair clips, keychains, and even garden tools often use torsion spring clips. Their ability to securely attach components while being simple to operate makes them versatile for a range of applications.

Key Advantages of Torsion Spring Clips

- Space-Efficient Design: One of the greatest advantages of torsion spring clips is their compact size. Despite their small footprint, they provide powerful and reliable fastening. This makes them ideal for applications where space is limited.

- Long-Lasting Durability: Torsion spring clips are built to withstand stress and constant use. Their robust materials allow them to function well even in challenging conditions, ensuring long-term reliability. Additionally, these clips are resistant to wear and tear, extending their lifespan.

- Quick and Easy Operation: The unique design of torsion spring clips allows for quick attachment and removal without the need for additional tools. This feature is especially valuable in industries like automotive manufacturing or when dealing with frequent adjustments.

- Energy Efficiency: Because torsion springs store and release energy effectively, they provide an energy-efficient way to secure components. They do so while minimizing the space required for the fastener, making them a sustainable option in many applications.

- Secure Attachment: The spring’s tension ensures a firm and secure grip. This guarantees that components remain firmly in place, reducing the risk of malfunction or accidental disconnection. The secure locking mechanism makes torsion spring clips ideal for high-stress environments.

Why Are Torsion Spring Clips Essential?

Torsion spring clips offer a unique combination of compactness, efficiency, and durability. In industries where secure fastening is critical—whether in automotive manufacturing, electronics, or consumer products—these clips provide a reliable and space-saving solution. Their simplicity, however, does not undermine their effectiveness; in fact, the very simplicity is what makes them so versatile.

However, as we consider the increasing demand for innovative fastening solutions, can torsion spring clips continue to hold their own as industries evolve? What new applications and advancements might push the limits of their design? The future of these clips could be brighter than ever, but only time will tell.

References:

- The Evolution of Spring Clips in Modern Manufacturing, Mechanical Design Review, February 2022.

- Applications of Torsion Spring Clips in Automotive Assembly, AutoTech Monthly, November 2021.