Technical Analysis of Automotive Spring Materials

1 Preamble

The Chinese automotive manufacturing industry, as the nation’s second pillar industry, has witnessed rapid growth. To promote the national economy, the industry must focus on the development, transformation, and high-quality expansion of Automotive Spring Materials. Notably, the spring industry, although relatively small, plays a vital role. And in Chinaese evolving automotive landscape, springs, as essential components, hold a pivotal position.

2 Application of springs in automobiles

Manufacturers use spring steel to craft springs. So choosing the right spring for a vehicle involves considering factors like load nature, direction, size, and operational conditions. This article provides an overview of springs in automobiles.

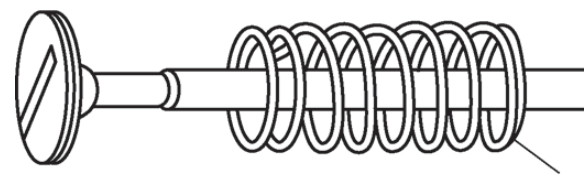

2.1 Coil springs

Coil springs, or suspension springs, are prevalent in Automotive Spring Materials used in automotive suspension systems, serving as elastic components that dampen vibrations alongside shock absorbers and guide mechanisms.

Figure 1

2.2 Leaf spring

Automotive leaf springs, or blade springs, consist of multiple stacked layers and play a critical role in vehicle suspensions.

Figure 2

Serpentine (bow) springs in vehicle seats are usually made from carbon spring steel wire or oil-quenched steel wire.

Figure 3

2.4 Valve springs

Valve springs ensure proper seating of engine valves to prevent leaks during engine vibration.

Figure 4

2.5 Stabilizer bar

Stabilizer bars, or anti-roll bars, limit excessive lateral roll during turns, enhancing stability and reducing body roll.

Figure 5

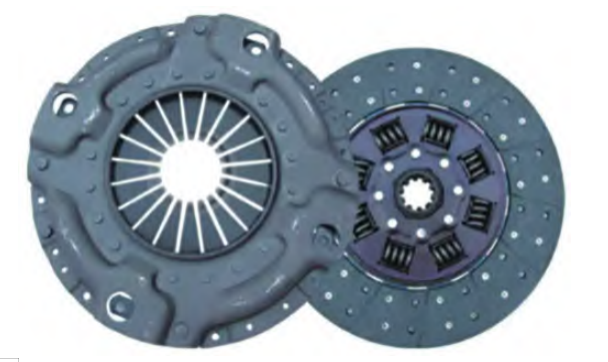

Automotive clutch diaphragm springs come in two main types: diaphragm springs and multi-reed types.

Figure 6

In addition to these components, various other spring steel parts include trunk support bars, ignition opening and closing return springs, car wiper springs, electronic accelerator pedal springs, handbrake return springs, etc., which will not be repeated here.

Besides, As a vital component of the automotive industry, springs operate within assembly environments. Optimizing structural design, ensuring surface quality, and using high-purity materials with appropriate heat treatment equipment enhance spring reliability and longevity.

IIn conclusion, “Automotive Spring Materials” are vital in the Chinese auto industry, impacting design and performance. Emphasizing quality and material optimization, they play a critical role in vehicle reliability. Springs contribute significantly to vehicle quality and overall industry growth.