Spring Manufacturing Process

Our advanced production facilities, seasoned engineers, and complete spring manufacturing process maximize productivity and bolster our competitiveness within the industry.

1. Materials Storage

By leveraging China’s robust raw material supply chain, we offer our customers a comprehensive range of materials for spring manufacturing. This includes high and low carbon steel, various grades of stainless steel (201, 302, 304, 316), 65Mn, Music Wire, Brass, Copper, Nickel, Inconel, Beryllium Copper, Bronze, Incoloy, Titanium, A286, MP35N, and other specialized alloys.

A large inventory of raw materials helps us to quickly provide our customers with customised spring products.

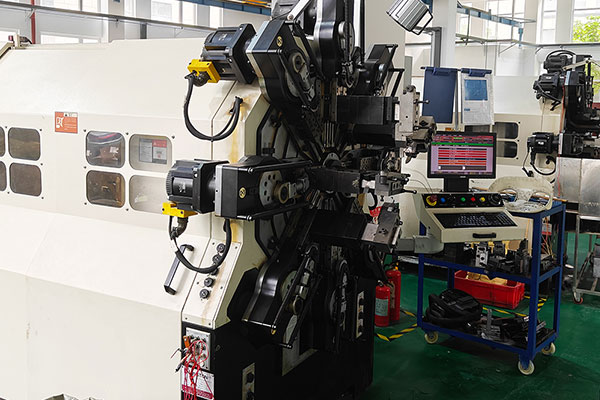

2. Spring Winding

There are 3 types of spring winding methods, spring wire is fed into our state-of-the-art CNC (computer numerical control) machines, where it undergoes initial straightening into straight before being shaped into the desired configuration.

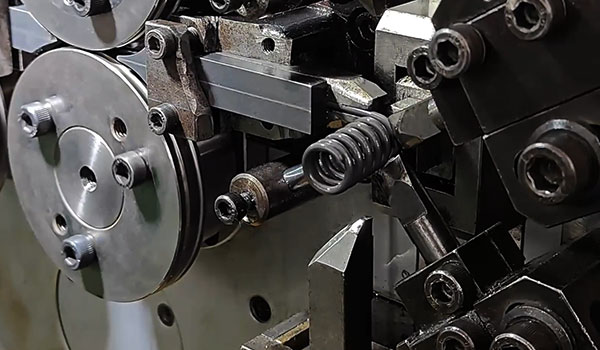

Spring Coiling Machine

Spring coilers guide wire through rollers and precision guides, culminating at a coiling point where the wire is looped backward to achieve the desired spring shape. This versatile process is employed to fabricate a wide range of custom spring designs, including tension, torsion, and compression springs.

Spring Forming Machine

We utilize forming machines for crafting compression, tension, torsion springs, and wire forms. A CNC spring-forming machine typically features six to eight tooling slides on its interface, enabling it to execute multiple bends and loops beyond standard spring coiling. This enhanced capability grants the machine greater flexibility compared to a traditional coiling machine.

Spring Bending Machine

Our CNC bending machines are computer-controlled and employ strategically positioned rollers to shape flat wire into customized wire form designs. Tool heads and guides maneuver the metal through the process, achieving the desired final design. These machines are preferred for producing high-quality wire forms and flat springs.

3. Spring Heat Treatment

Heat treatment is a valuable process that enhances the material quality of springs. By subjecting metal alloys to controlled heating and cooling cycles, the crystalline structure undergoes modification. This process, conducted at varying intensities and durations, results in improved durability, increased resistance to higher temperatures, and enhanced ductility.

Hardening

Metal hardening involves heating alloys above their critical temperature and then rapidly cooling them. While some metals are hardened alone, most undergo additional treatments like tempering or stress relieving to enhance workability and toughness.

Tempering

After hardening, tempering reduces the strain on the metal. This process further refines the material’s properties and balances them out. Specific tempering conditions vary based on desired outcomes and metal types. Generally, tempering involves reheating the cooled metal at a lower temperature, promoting chemical precipitation and spheroidization of internal elements. Spheroidization is particularly relevant for compression springs.

Annealing

Annealing aims to enhance ductility by making metals more malleable without fracturing. This process reduces hardness by minimizing dislocations in the metal’s crystalline structure. Annealing is typically applied to cold-worked or hardened materials to prevent brittleness and improve overall performance.

4. Coating and Finishing

In the last stage of spring manufacturing, we apply coatings, platings, or other finishing processes. While heat treatment enhances internal metal quality, this phase focuses on refining the external surface. Our goal is to maximize the longevity of our springs by applying effective coatings that resist corrosion and enhance visual appeal.

We have a variety of surface treatment processes including:

- Plating: zinc plating, nickel plating, tin plating, gold/silver plating, copper plating, chorme plating, etc.

- Black Oxided

- Anodic Oxidation

- Electrophoresis

- Powder Coating

- Oil Coating

- Sand Blasting

- Passivation

- Polishing

- And More

Strict Quality Inspection Process

Our comprehensive spring production process and advanced technology enable us to fulfill diverse customer requirements effectively. Rigorous quality inspection further enhances the products and systems of our customers.