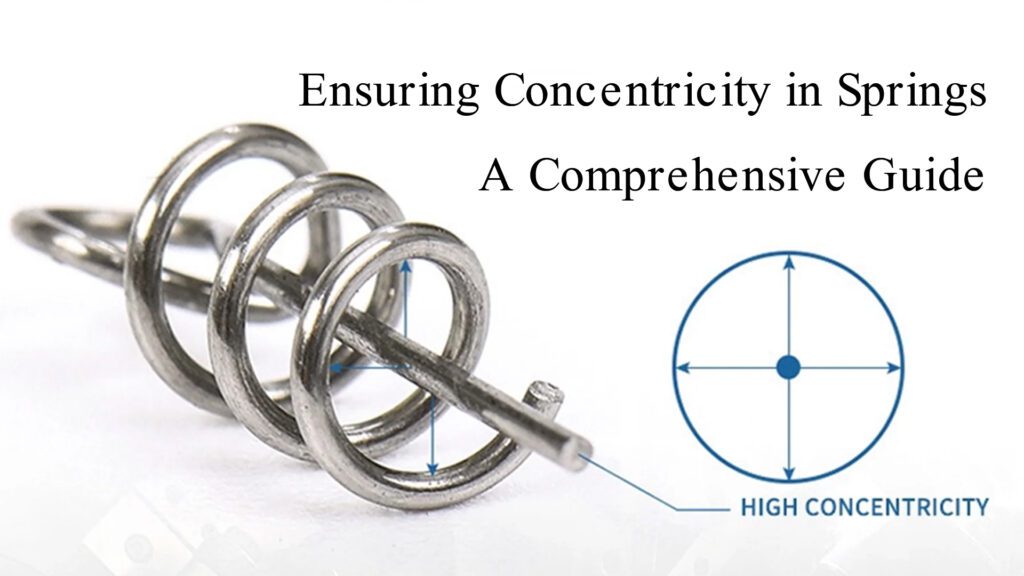

Concentricity in springs is a critical factor influencing their performance, durability, and reliability. Achieving and maintaining concentricity ensures that the spring operates smoothly and efficiently, reducing the risk of misalignment and uneven wear. This guide delves into the importance of concentricity, its impact on spring performance, and the methods used to ensure precise alignment.

What is Concentricity in Springs?

Concentricity refers to the condition where all the coils of a spring center around a common axis. In other words, the coils align perfectly in a circular pattern without any deviation. This alignment is crucial for the spring to function correctly, providing uniform force and movement.

Importance of Concentricity

First and foremost, concentricity is essential for performance. Concentric springs provide consistent force and torque, ensuring smooth and reliable operation in various applications. Misaligned coils can lead to uneven force distribution, causing performance issues.

In addition, springs with high concentricity experience less wear and tear, as the uniform distribution of stress reduces the likelihood of premature failure. This extends the lifespan of the spring.

Furthermore, in applications requiring precise movement and control, such as in medical devices or aerospace components, concentricity is essential to achieve the desired accuracy and functionality.

Moreover, ensuring concentricity reduces the risk of mechanical failures that could lead to safety hazards, particularly in critical applications like automotive suspensions or industrial machinery.

Methods to Ensure Concentricity

To achieve concentricity, precision manufacturing processes such as CNC (Computer Numerical Control) machining and advanced coiling technologies are employed. These techniques ensure that each coil is formed accurately.

Using high-quality materials with consistent properties also helps achieve uniform coil formation. Variations in material properties can lead to inconsistencies in the spring’s shape and alignment.

Moreover, rigorous quality control measures, including visual inspections and automated testing, detect and correct any deviations in concentricity during the manufacturing process.

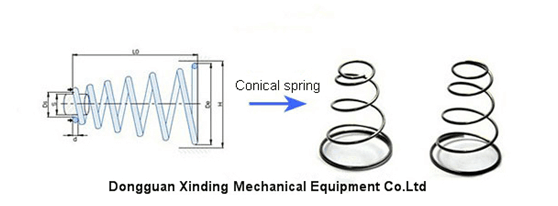

Designing springs with appropriate tolerances and considering factors such as wire diameter, coil diameter, and the number of coils can also help maintain concentricity. Proper design minimizes the risk of misalignment during operation.

Proper installation techniques are crucial to maintaining concentricity. Ensuring that the spring is mounted correctly and that any associated components are aligned helps prevent deformation. Regular maintenance and inspections can identify any issues early and allow for corrective actions.

Applications Benefiting from High Concentricity

In the automotive industry, concentric springs ensure smooth and reliable operation, enhancing ride comfort and handling.

In aerospace applications, concentric springs maintain the accuracy and reliability of components that require precise movement and control.

Medical devices also benefit from concentric springs, as they provide the precision needed for delicate operations and consistent performance.

Furthermore, industrial machinery often involves heavy loads and repetitive movements. Concentric springs ensure the machinery operates efficiently and reduce the risk of mechanical failures.

Finally, in consumer electronics, precision and reliability are crucial. Concentric springs ensure consistent performance in applications such as switches and connectors.