1. Double spring lock buckle

The double spring buckle mainly reflects that it has spring design on both sides, which can play the role of tightening and buffering.

In various devices with vibration and frequent opening and moving, severe vibration will be generated. At this time, the double spring buckle on the equipment can offset these vibrations through the springs on both sides, and at the same time play the role of tightening, and will not force the tightened buckle to loosen due to vibration.

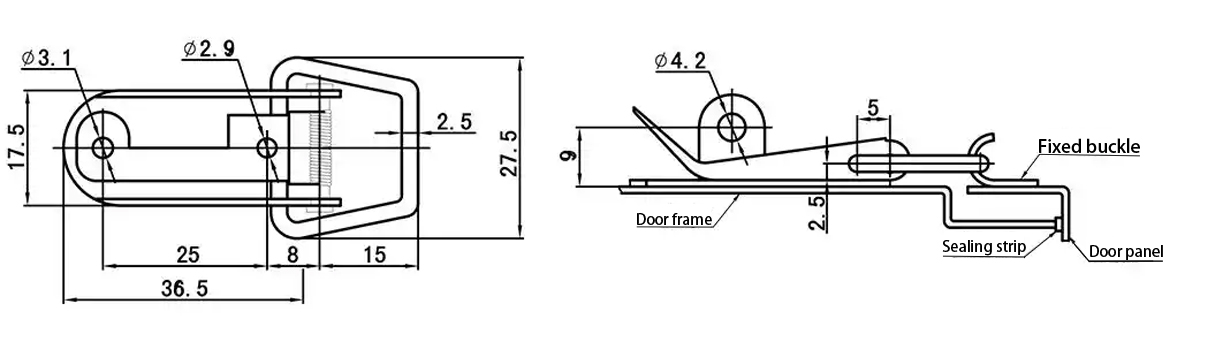

2. Built-in spring buckle

Automatic reset rebound, fast opening and closing.

It can also be customized with or without lock buckle, with padlock hole has a certain anti-theft function, it is a buckle lock with strong safety performance

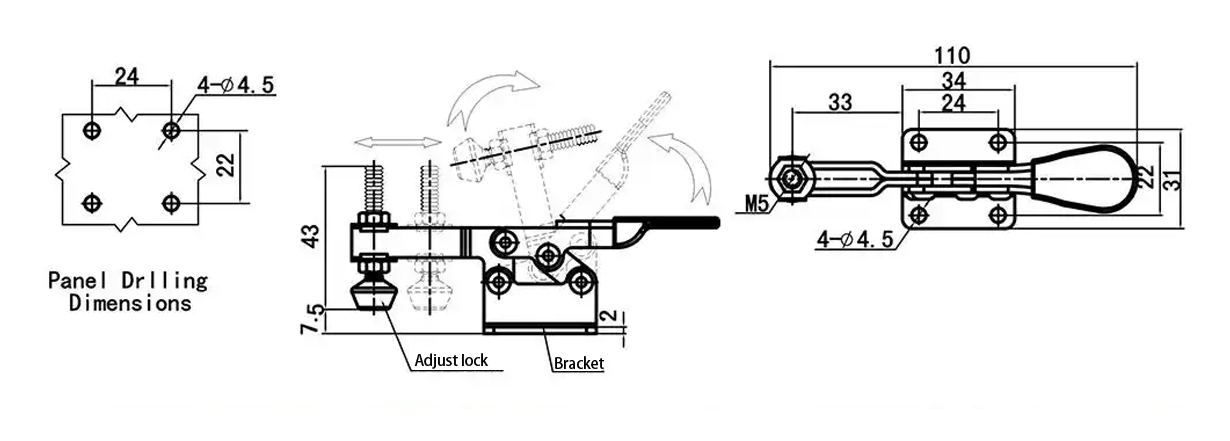

Adjustable buckle

The screw/tension is adjustable, and the tightening activity is strong, so as to achieve a wider range of applications.

The adjustable buckle is generally a triangular head with a screw below. The so-called adjustability is to achieve the purpose of adjustability by changing the length of the screw through the screw hole. The adjustable range depends on the length of the screw.

Adjustable buckles have significant advantages such as good load-bearing, no deformation, quick opening and closing, and space saving.

Clamp/hinge clamp

A manual clamp used for positioning, clamping, etc.

Because it is easy to operate and can provide stable clamping force and processing efficiency, it is widely used in welding processing, machining, inspection fixtures/molds, assembly and other production processes.

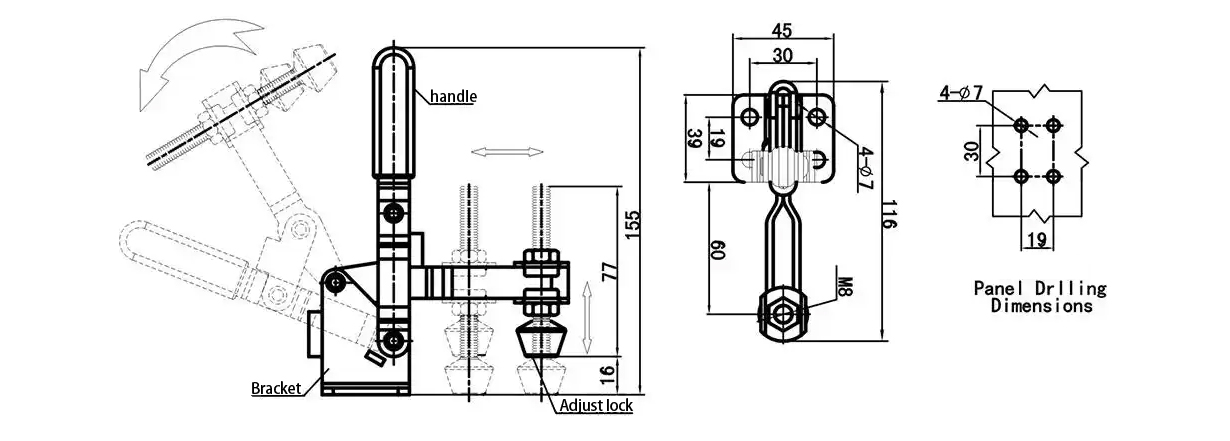

1. Vertical clamp

The operating handle moves in the same direction as the clamping arm. In the clamped state, the operating handle is in a vertical position.

Can be used in situations where extremely high clamping force is required.

2. Horizontal clamp

The operating handle moves in the opposite direction to the clamping arm. In the clamped position, the operating handle is in a horizontal position.

Suitable for clamping workbenches near the outside.