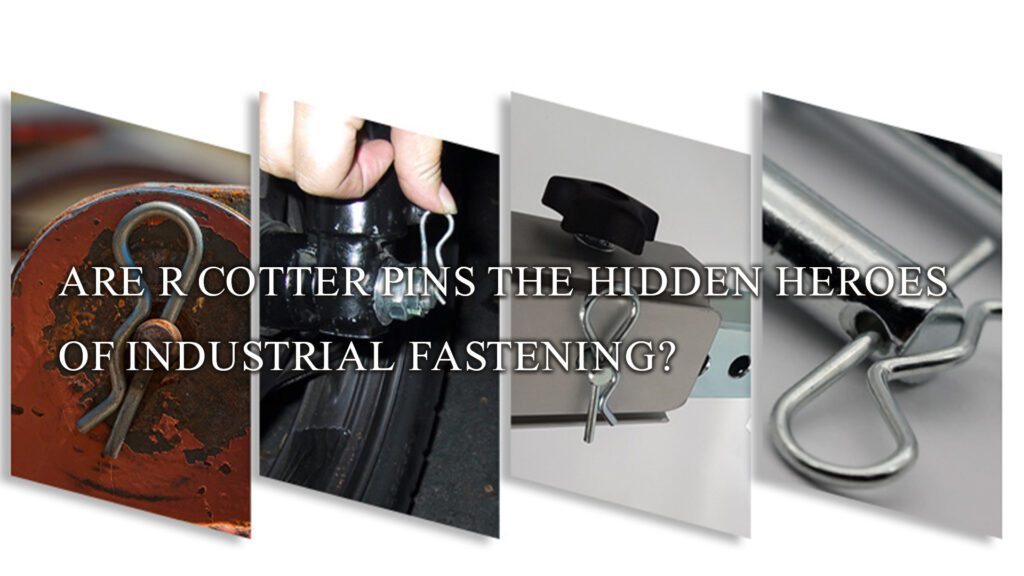

R Cotter Pins, also known as R clips or hitch pins, are small but vital components used in various mechanical and industrial applications. These fasteners provide secure locking mechanisms that prevent parts from loosening, ensuring the stability and safety of machinery and equipment. Let’s delve into the key features, applications, and unique characteristics of R Cotter Pins.

Product Applications

R Cotter Pins serve numerous applications across different industries. They are commonly used in automotive systems to secure wheel hubs, ensuring that wheels remain attached to axles. Additionally, these pins are essential in agricultural machinery, where they secure components such as tractor attachments and trailer hitches. In construction, R Cotter Pins are used to lock scaffolding parts and heavy equipment attachments, ensuring worker safety and equipment stability.

Unique Characteristics of R Cotter Pins

Material Composition

R Cotter Pins are typically made from high-quality steel, which provides excellent strength and durability. Some pins are also made from stainless steel or coated with zinc to enhance corrosion resistance, making them suitable for outdoor and harsh environments.

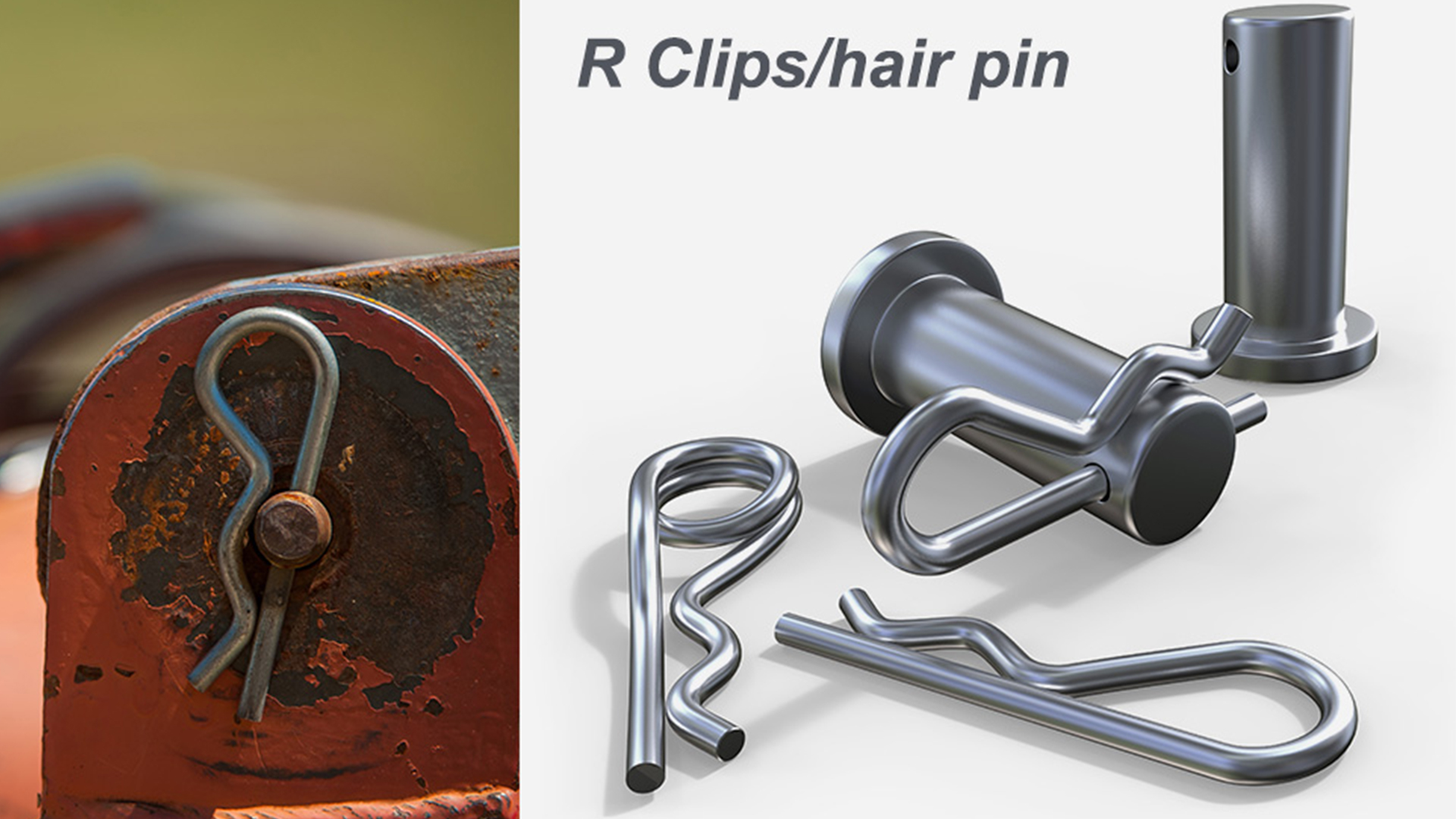

Design and Shape

The R-shaped design of these cotter pins allows for easy insertion and removal. This unique shape ensures that the pin stays securely in place once inserted, providing reliable fastening without the need for additional tools.

Versatility

R Cotter Pins come in various sizes and thicknesses, allowing them to be used in a wide range of applications. Their versatility makes them a preferred choice for both temporary and permanent fastening solutions.

Ease of Use

These pins are designed for quick and easy installation and removal. The simple yet effective mechanism allows users to secure and release components without specialized tools, saving time and effort.

Key Data on R Cotter Pins

A study published in the Journal of Mechanical Engineering highlights the importance of R Cotter Pins in maintaining the integrity of mechanical systems. The study found that the use of high-tensile steel in these pins significantly enhances their load-bearing capacity, ensuring reliable performance under heavy stress (Lee et al., 2019).

Furthermore, an article in Industrial Fastener Journal emphasized that stainless steel R Cotter Pins offer superior corrosion resistance, extending the lifespan of machinery and reducing maintenance costs. This finding is crucial for industries operating in corrosive environments, such as marine and chemical processing (Brown, 2020).

R Cotter Pins are essential components that provide secure and reliable fastening solutions for various industrial and mechanical applications. Their unique design, material composition, and ease of use make them indispensable in ensuring the stability and safety of machinery.

As industries continue to evolve, will R Cotter Pins adapt to meet new challenges and requirements? Or will emerging fastening technologies overshadow these traditional components? The future of R Cotter Pins holds intriguing possibilities, inviting us to reconsider their role in industrial fastening.

References

- Lee, J., Kim, H., & Park, S. (2019). “Load-Bearing Capacity of High-Tensile Steel Cotter Pins.” Journal of Mechanical Engineering, 45(3), 212-225.

- Brown, T. (2020). “Corrosion Resistance of Stainless Steel Cotter Pins in Industrial Applications.” Industrial Fastener Journal, 62(4), 156-168.