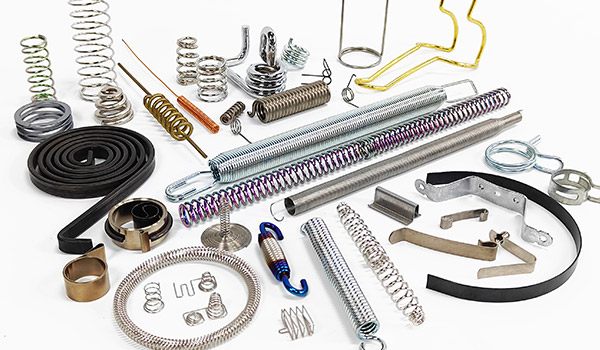

Complete Spring Manufacturing Service

In industries and applications demanding specialized spring manufacturing service processes and equipment for optimal spring performance and longevity, our proficient team collaborates closely with you. Together, we craft, enhance, and fine-tune spring designs to exact tolerances, performance standards, and specific use scenarios.

Equipped with a comprehensive array of spring production processes and state-of-the-art equipment, we stand ready to fulfill all our customers’ spring design and manufacturing requirements.

Core Spring Manufacturing Service

Coiling

Spring Bending

Spring Forming

Molding Die Spring

Hot Forging

Laser Cutting

Stamping & Forming

Wire Forming

Welding

Materials and Wire Types

Wire Diameter 0.08~35 mm

Round Wire

Rectangular Wire

Flat Wire

Stranded Wire

Carbon Steel

Stainless Steel (201/302/304/316)

Music Wire

65Mn

60Si2Mn

Nickel

Titanium

Copper

Inconel

And More…

Spring Coating and Finishing

Grinding

Heat Treatment

Tempering

Annealing

Polishing

Color Plating

Zinc Plating

Dyeing

Powder Coating

Electrophoresis

Sand Blasting

Passivation

Plastic Spraying

Oxidation

And More…

Value Added Service

Engineering Support

CAD Modeling

Designing Service

Performance Analysis & Testing

Sample Testing

Assembly

If you’re creating a spring, reach out to our engineering team for assistance. We’ll ensure you’re connected with the appropriate expert who can provide the support you need.