Manufacturing Industry

20+ Years

Spring Manufacturer Experience

5000+㎡

Production Workshop

20+

Experienced Engineers

Unlimited

Custom Capabilities

About Manufacturing Industry springs

In the manufacturing industry, springs are integral components in a wide range of equipment and processes. They provide mechanical force, absorb energy, and enable precise control in various applications. Here are some specific areas where springs are used in the manufacturing industry:

Machine Tools:

- CNC Machines: Springs are used in tool changers, clamps, and tensioning systems to ensure precise tool positioning and secure workpiece holding.

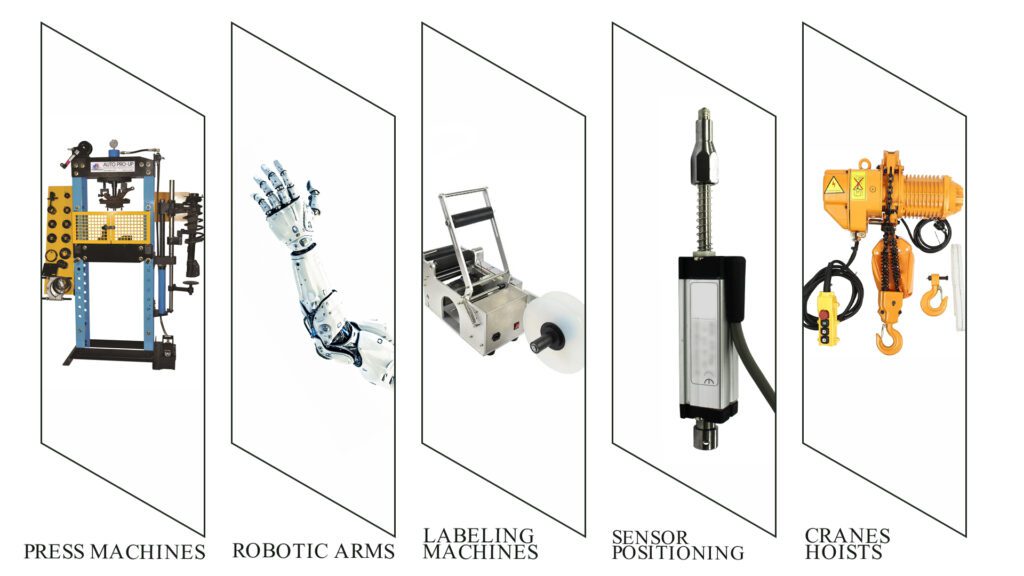

- Press Machines: Springs provide the return force in stamping and forming presses, enabling repetitive operations with high precision.

- Lathe Machines: Springs help control tool movement and ensure consistent pressure during the machining process.

Assembly Lines:

- Conveyor Systems: Springs are used in tensioning mechanisms to maintain belt or chain tension, ensuring smooth and continuous material flow.

- Pneumatic and Hydraulic Actuators: Springs assist in controlling movement and pressure in actuators, providing consistent performance in automated assembly lines.

- Part Feeders: Springs are used to control vibration and movement in part feeding systems, ensuring accurate placement of components.

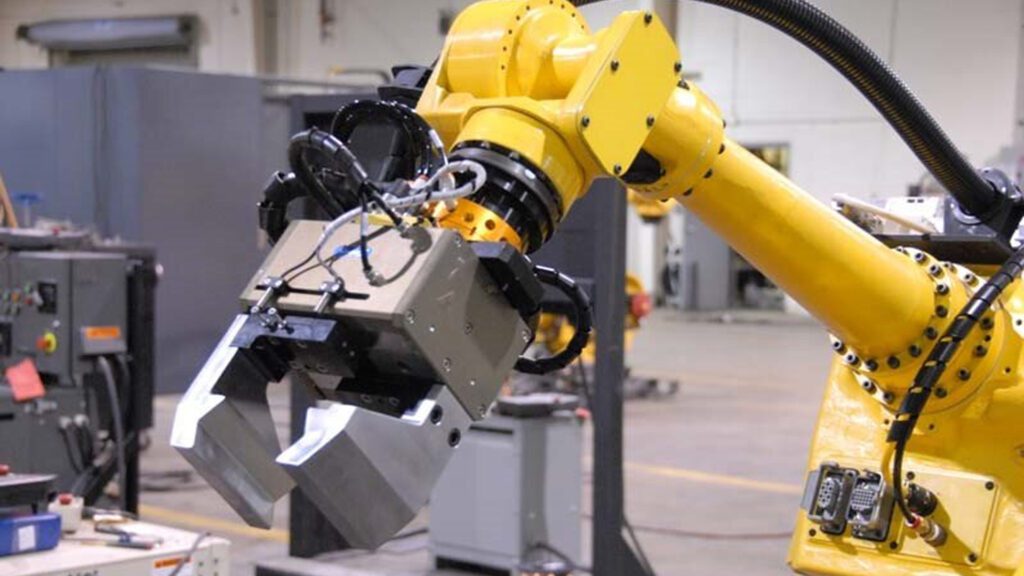

Robotic Systems:

- Robotic Arms: Springs provide counterbalance and assist in controlling the movement of robotic arms, improving precision and reducing energy consumption.

- End Effectors: Springs are used in grippers and tools attached to robotic arms to maintain consistent force when handling delicate or variable-sized objects.

Packaging Machinery:

- Filling and Sealing Machines: Springs are used in valves, actuators, and clamps to ensure precise and consistent filling and sealing of packages.

- Labeling Machines: Springs control the pressure and movement of labeling heads, ensuring accurate placement of labels on products.

- Wrapping Machines: Springs assist in the tensioning and cutting mechanisms of wrapping machines, ensuring smooth and secure packaging.

Injection Molding Machines:

- Mold Clamping: Springs provide the necessary force to keep the mold closed during the injection process, ensuring consistent product quality.

- Ejection Systems: Springs are used in ejector pins to push the finished product out of the mold cavity without damaging it.

Automated Inspection Systems:

- Sensor Positioning: Springs help maintain the correct positioning of sensors and cameras in automated inspection systems, ensuring accurate detection and measurement.

- Sorting Mechanisms: Springs are used in gates and diverters to sort products based on inspection results, ensuring efficient handling.

Material Handling Equipment:

- Lift Tables and Elevators: Springs are used to balance loads and assist in lifting, providing smooth and controlled vertical movement.

- Cranes and Hoists: Springs are used in braking and tensioning systems to ensure safe and precise operation during material handling.

Press and Stamping Tools:

- Die Springs: These heavy-duty springs are used in stamping dies to absorb shock and return the die to its original position after each press.

- Punching Machines: Springs are used in punch return systems to ensure the tool returns to its starting position after each punch.

Vibratory Equipment:

- Vibrating Screens and Feeders: Springs provide the necessary oscillation force in vibrating equipment used for sorting, feeding, and separating materials.

- Vibrating Conveyors: Springs help in the smooth and controlled movement of materials on vibrating conveyors, ensuring efficient processing.

Maintenance and Safety Systems:

- Braking Systems: Springs are used in emergency braking mechanisms for machinery, ensuring quick and reliable stops in case of malfunction.

- Tensioning Devices: Springs maintain tension in belts, chains, and cables, preventing slippage and ensuring safe and efficient operation.

Energy Absorption and Damping:

- Shock Absorbers: Springs are used in shock absorbers to absorb and dissipate energy in machinery, protecting components from damage due to vibrations or impacts.

- Vibration Isolators: Springs are used to isolate machinery from vibrations, reducing noise and preventing wear and tear on sensitive components.

Testing Equipment:

- Load Testing Machines: Springs are used to apply controlled force in testing equipment, ensuring accurate measurements of material strength and durability.

- Fatigue Testing Systems: Springs simulate repetitive stress in testing equipment to evaluate the longevity and performance of materials and components.

These examples highlight the critical role springs play in the manufacturing industry, contributing to the efficiency, precision, and safety of various manufacturing processes and equipment.

Why choose Hengsheng Spring?

Quality

Strict Quality Control: Rigorous workflows ensure that every product meets or even exceeds customer expectations.

Certifications and Standards: Obtained relevant international and domestic quality certifications (ISO, CE, ROHS, etc.)

Price

Reasonable pricing strategy: Provide competitive prices by optimizing production and logistics costs.

Transparent pricing mechanism: Let customers clearly understand the composition and advantages of the price

Custom

Personalized customization: Provide customized products and services according to the specific needs of customers.

Quick response: Quickly handle customers’ customized needs and feedback to improve customer satisfaction.

R&D

Innovative products: Continuously launch new products to meet the changing needs of the market and customers.

Technical advantages: Possess independent intellectual property rights and patented technologies to enhance the technical content and added value of products

Manage

Stable supply chain: Ensure the stability of raw materials and production links and ensure timely delivery of products.

Efficient logistics system: By optimizing logistics channels, we ensure that products can be delivered to customers quickly and accurately.

Serve

Pre-sales service: Provide professional consultation and advice to help customers make wise

choices. After-sales service: Establish a complete after-sales service system to solve customer problems and needs in a timely manner

Brand

Brand building: Establish a good corporate image and market reputation through brand promotion and marketing activities.

Customer reputation: Win the trust and loyalty of customers through high-quality products and services.

Market

International market expansion: Actively explore international markets and expand brand influence and market share.

Localization services: Set up offices or partners in major markets to provide localized support and services.

EP&CSR

Green production: Use environmentally friendly materials and production processes to reduce environmental impact.

Social Responsibility: Actively fulfill social responsibilities, participate in public welfare activities, and enhance the corporate social image.

Progress

Customer feedback mechanism: Establish an effective customer feedback mechanism to continuously improve products and services.

Employee training: Improve employees’ professional capabilities and service levels through continuous employee training.

Contact Us

Need help with pricing or technical questions about custom springs? Or any other product-related assistance? Our team is equipped with sales professionals, design engineers, and manufacturing experts ready to address your needs. We’ll make sure you’re connected with the person most qualified to help.

Chat with Us

+86 13328669695

Email Us

shelly.wang@hengshengspring.com

Address

NO.12, Liandong U Valley , Yangxia Industrial Strict, Fuqing, Fuzhou, Fujian, China