Finishing Tools

20+ Years

Spring Manufacturer Experience

5000+㎡

Production Workshop

20+

Experienced Engineers

Unlimited

Custom Capabilities

About Finishing Tools springs

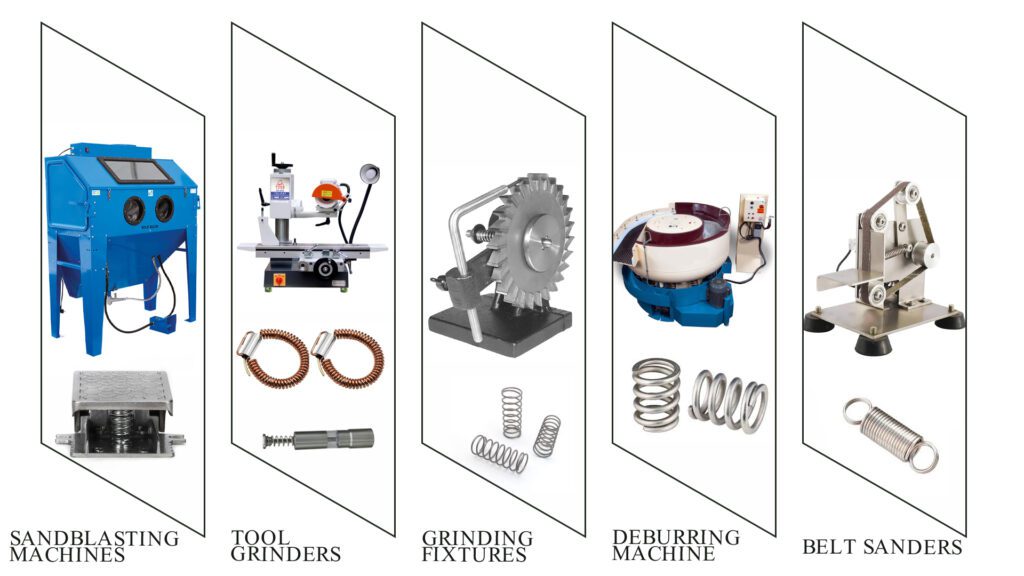

Springs are widely used in the finishing tools sector, providing precise control, enhancing functionality, and improving efficiency in various tools and equipment. Here are some specific applications of springs in this field:

Grinders and Polishers:

- Grinding Heads and Polishing Discs: Springs are used to adjust the pressure of the grinding heads and polishing discs, ensuring consistent contact and uniform finishing quality.

- Vibration Mechanisms: Springs generate vibrations to help remove surface irregularities and enhance surface smoothness.

Sanders and Belt Sanders:

- Tensioning Mechanisms: Springs are used to tension sandpaper and sanding belts, ensuring their stability and efficiency during operation.

- Pressure Control: Springs adjust the pressure of the sandpaper or sanding belt, allowing them to adapt to different materials and finishing needs.

Deburring Tools:

- Rotary Deburring Tools: Springs control the position and pressure of the cutting tools, ensuring uniform deburring and surface quality.

- Manual Deburring Tools: Springs provide return force, making the tools more flexible and efficient to use.

Precision Grinding Tools:

- Grinding Fixtures: Springs are used to secure and adjust the position of workpieces, ensuring precise grinding angles and uniform grinding results.

- Automatic Feed Mechanisms: Springs control the feed rate of grinding materials, ensuring a stable and consistent grinding process.

Polishing Tools:

- Polishing Wheels: Springs adjust the pressure and contact surface of polishing wheels, ensuring uniform polishing results.

- Automatic Polishing Machines: Springs control the movement and pressure of polishing heads, achieving efficient and precise surface treatment.

Sanding Machines:

- Handheld Sanders: Springs adjust the pressure and position of the sanding heads, improving operational flexibility and finishing quality.

- Stationary Sanders: Springs are used to tension and adjust sanding belts or discs, ensuring stability during operation.

Precision Tool Holders:

- Spring Collets: Springs are used to hold tools or workpieces securely, ensuring stability and accuracy during machining.

- Quick-Change Fixtures: Springs enable quick changing of tools or workpieces, improving work efficiency.

Automated Finishing Equipment:

- Robotic Grinding and Polishing Systems: Springs control the pressure and position of tools, achieving high precision and efficiency in automated processes.

- Conveyor Systems: Springs are used to tension and adjust conveyor belts, ensuring stable transfer of workpieces during finishing.

Surface Treatment Equipment:

- Sandblasting Machines: Springs control the pressure and angle of the sandblasting gun, ensuring uniform surface treatment results.

- Spray Coating Equipment: Springs adjust the pressure and spray angle of the coating heads, achieving precise coating thickness and uniformity.

Tool and Cutter Maintenance:

- Tool Grinders: Springs adjust grinding angles and pressure, ensuring precise sharpening of tools and cutters.

- Sharpening Tools: Springs control the movement and pressure of grinding heads, achieving efficient and high-quality sharpening.

These applications illustrate the extensive use of springs in the finishing tools sector. Springs not only enhance the functionality and efficiency of tools and equipment but also ensure the precision and consistency of the finishing process.

Why choose Hengsheng Spring?

Quality

Strict Quality Control: Rigorous workflows ensure that every product meets or even exceeds customer expectations.

Certifications and Standards: Obtained relevant international and domestic quality certifications (ISO, CE, ROHS, etc.)

Price

Reasonable pricing strategy: Provide competitive prices by optimizing production and logistics costs.

Transparent pricing mechanism: Let customers clearly understand the composition and advantages of the price

Custom

Personalized customization: Provide customized products and services according to the specific needs of customers.

Quick response: Quickly handle customers’ customized needs and feedback to improve customer satisfaction.

R&D

Innovative products: Continuously launch new products to meet the changing needs of the market and customers.

Technical advantages: Possess independent intellectual property rights and patented technologies to enhance the technical content and added value of products

Manage

Stable supply chain: Ensure the stability of raw materials and production links and ensure timely delivery of products.

Efficient logistics system: By optimizing logistics channels, we ensure that products can be delivered to customers quickly and accurately.

Serve

Pre-sales service: Provide professional consultation and advice to help customers make wise

choices. After-sales service: Establish a complete after-sales service system to solve customer problems and needs in a timely manner

Brand

Brand building: Establish a good corporate image and market reputation through brand promotion and marketing activities.

Customer reputation: Win the trust and loyalty of customers through high-quality products and services.

Market

International market expansion: Actively explore international markets and expand brand influence and market share.

Localization services: Set up offices or partners in major markets to provide localized support and services.

EP&CSR

Green production: Use environmentally friendly materials and production processes to reduce environmental impact.

Social Responsibility: Actively fulfill social responsibilities, participate in public welfare activities, and enhance the corporate social image.

Progress

Customer feedback mechanism: Establish an effective customer feedback mechanism to continuously improve products and services.

Employee training: Improve employees’ professional capabilities and service levels through continuous employee training.

Contact Us

Need help with pricing or technical questions about custom springs? Or any other product-related assistance? Our team is equipped with sales professionals, design engineers, and manufacturing experts ready to address your needs. We’ll make sure you’re connected with the person most qualified to help.

Chat with Us

+86 13328669695

Email Us

shelly.wang@hengshengspring.com

Address

NO.12, Liandong U Valley , Yangxia Industrial Strict, Fuqing, Fuzhou, Fujian, China