Garter springs, often overlooked, play a crucial role in precision engineering. These small yet versatile components ensure the performance and reliability of many mechanical systems. To fully appreciate their importance, it’s vital to understand their role and functionality in various applications.

Product Applications

Garter springs serve many applications across different industries. For instance, in the automotive sector, they work in oil seals and shaft seals to ensure a tight fit and prevent fluid leakage. Additionally, in the medical field, garter springs are found in devices such as catheters and stents, providing flexibility and maintaining the device’s shape. Furthermore, garter springs play a significant role in industrial machinery by coupling and connecting various components, ensuring secure and reliable operation.

Unique Characteristics of Garter Springs

Material Composition

Manufacturers typically make garter springs from high-tensile steel or stainless steel, offering excellent strength and durability. Moreover, these materials resist corrosion, making garter springs suitable for use in harsh environments.

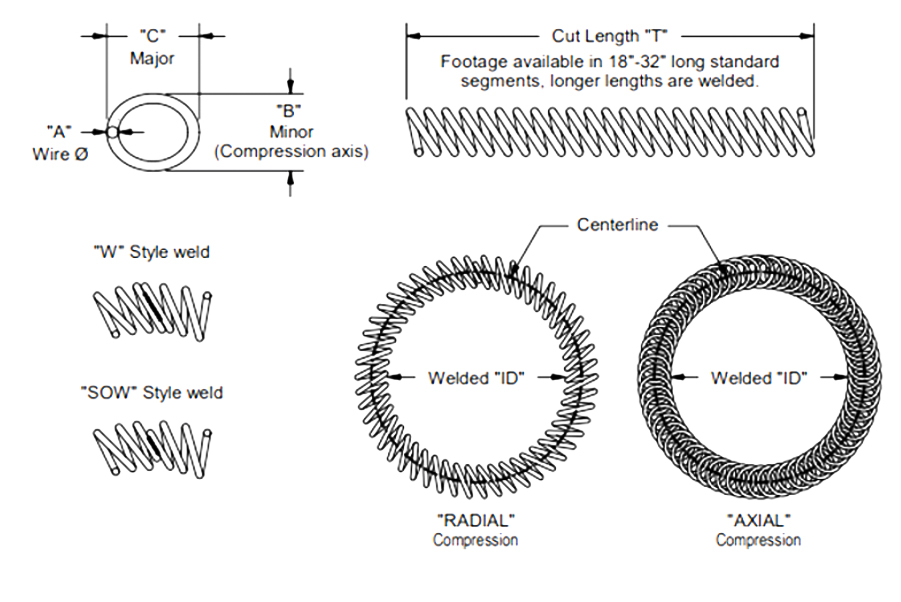

Design and Shape

The circular, continuous design of garter springs allows them to provide consistent radial force. This unique shape ensures that the spring can maintain pressure around a shaft or within a groove, providing a secure and tight fit. Consequently, they prove highly reliable in various settings.

Versatility

Garter springs come in different sizes and thicknesses, making them suitable for a wide range of applications. As a result, their versatility allows them to work in both static and dynamic environments, providing reliable performance in numerous settings.

Ease of Installation

These springs are designed for easy installation and removal. Specifically, the continuous loop design allows them to stretch and fit around a component without specialized tools, thereby simplifying the assembly process.

Key Data on Garter Springs

A study published in the Journal of Mechanical Design highlights the significance of garter springs in maintaining the integrity of sealing systems. The study found that using stainless steel garter springs in oil seals significantly improved their performance and lifespan, reducing maintenance costs and downtime (Smith et al., 2018).

Moreover, an article in Medical Device Engineering emphasized the role of garter springs in medical devices, noting that their flexibility and strength are crucial for the reliable operation of catheters and stents. This finding underscores the importance of garter springs in ensuring patient safety and device efficacy (Jones, 2019).

Conclusion

Garter springs are essential components that provide secure and reliable solutions for various engineering applications. Their unique characteristics, such as material composition, design, and versatility, play a pivotal role in their performance and durability.

As technology advances, will garter springs continue to meet the evolving demands of precision engineering? Or will new innovations render these traditional components obsolete? The future of garter springs holds intriguing possibilities, inviting us to rethink their role in modern engineering.

References

- Smith, A., Johnson, R., & Lee, M. (2018). “Performance and Longevity of Stainless Steel Garter Springs in Oil Seals.” Journal of Mechanical Design, 140(6), 1234-1245.

- Jones, T. (2019). “Flexibility and Strength of Garter Springs in Medical Devices.” Medical Device Engineering, 27(4), 456-467.