Exploring the Dynamics and Applications of Hinge Springs in Modern Engineering

Introduction:

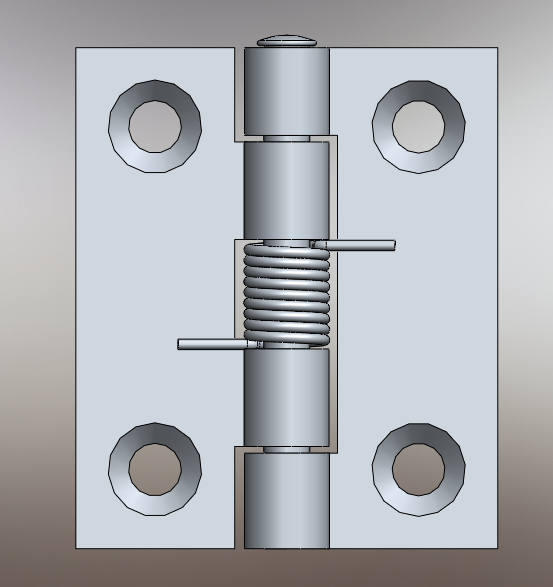

Hinge springs are mechanical components commonly found in various applications, especially in devices where controlled movement and closure are essential, like doors, cabinets, or lids. These springs are designed to assist or control the motion of a hinge, ensuring smooth opening and closing actions while providing resistance or force to maintain the desired position.

Materials Used in Hinge Spring:

Hinge spring are typically made from materials such as:

- Stainless Steel: Known for durability and corrosion resistance.

- Carbon Steel: Offers strength and is cost-effective.

- Alloys (Bronze, Brass): Used for corrosion resistance or aesthetics.

- Plastics/Composites: Lightweight and cost-effective in some applications.

Applications:

Explore the diverse range of applications for hinge spring, including but not limited to:

- Furniture: Cabinets, doors, and desks

- Automotive: Trunk lids, glove compartments

- Aerospace: Aircraft compartments, doors

- Industrial machinery: Equipment with moving parts

- Medical devices: Surgical instruments, equipment housing

Advantages of Hinge Springs:

Highlight the advantages offered by hinge spring, such as:

- Facilitating smooth and controlled movement

- Reducing stress on hinge mechanisms

- Preventing abrupt slamming or damage

- Enhancing the durability of hinges and related components

Effects on Daily Life:

Hinge springs in daily life:

- Smooth Movement: Enable gentle opening and closing, preventing slamming.

- Longevity: Reduce wear on hinges, extending product lifespan.

- Safety: Prevent accidents from sudden closures.

- Convenience: Enhance usability in daily activities.

Conclusion:

Hinge springs, constructed from materials like stainless steel, carbon steel, alloys, or plastics, quietly impact daily life. They ensure smooth, safe movement in doors and lids, extend item lifespans, and seamlessly integrate convenience into our routines. These unassuming components exemplify the fusion of precision engineering and everyday practicality, enriching our lives through their understated yet indispensable presence. Finally, we will take you have a look on the manufacturing of hinge spring. Pls follow us to know more detail.