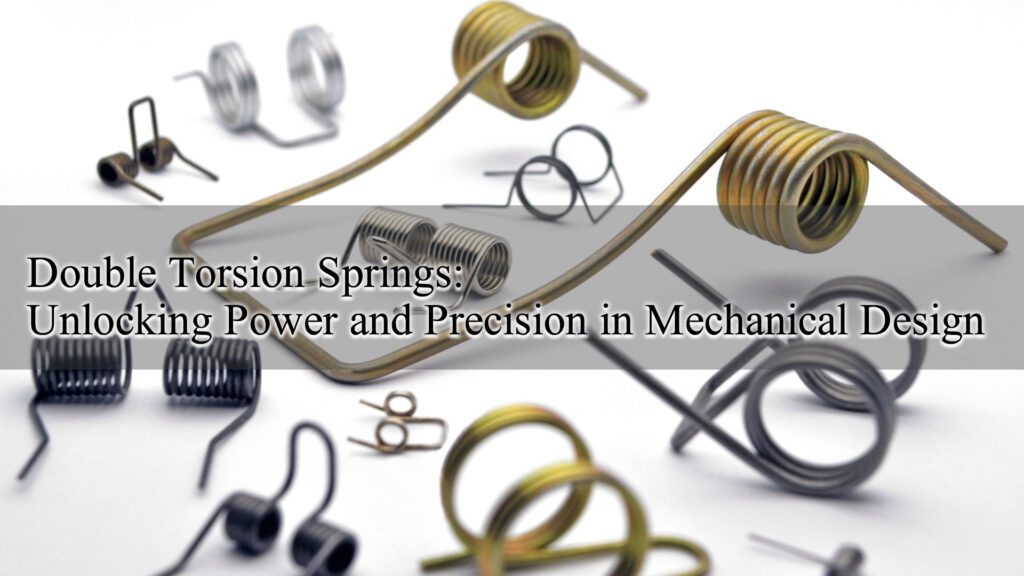

A double torsion spring is a special type of spring designed to provide torque in both directions. The spring is crafted by winding two torsion springs in opposite directions around a central core, allowing it to deliver consistent, precise rotational force. These springs are essential in numerous mechanical systems, where they help control energy storage, torque, and motion.

What Makes Double Torsion Springs Stand Out?

Double torsion springs are not just ordinary mechanical components—they are highly efficient at storing and releasing energy. By twisting the spring, you generate torque, which the spring then slowly releases when unwound. Their unique design and functionality make double torsion springs indispensable in several high-precision applications.

- Effective Torque Control: Double torsion springs excel at controlling torque with remarkable precision. In automotive systems, for instance, these springs help control components like latches and seat mechanisms, ensuring smooth operation and reliability.

- Space-Efficient Design: Thanks to their compact size, double torsion springs provide high torque without taking up excessive space. This compact design makes them ideal for industries where space is limited but high performance is still required.

- Reliable Energy Storage: Double torsion springs efficiently store energy when twisted. The energy is gradually released, making them perfect for applications where a controlled and consistent force is needed over time.

Key Applications of Double Torsion Springs

- Automotive Industry: Double torsion springs are used in various automotive components, such as door latches, seat recliners, and locks. These springs reliably control torque and contribute to the smooth operation of automotive systems.

- Industrial Machinery: In heavy machinery, double torsion springs help control essential components like clutches, gears, and valves. Their ability to manage rotational forces efficiently makes them indispensable in industrial settings.

- Consumer Products: From retractable pens to paper clips and door closers, double torsion springs play a crucial role in the everyday items we use. They provide the energy needed to power repetitive movements and mechanical functions.

- Toys and Gadgets: Many mechanical toys rely on double torsion springs for motion. These springs store the necessary energy to power movements in wind-up toys and other small devices.

- Aerospace and Military: Double torsion springs are also essential in the aerospace and military sectors. They are used to control movements in critical components, such as landing gear, ensuring reliable performance in high-stakes environments.

Why Double Torsion Springs Are Irreplaceable

- Durability and Longevity: Double torsion springs are built to last. Their robust design ensures they can withstand repeated use and remain effective over time, even in harsh environments.

- Compact Yet Powerful: Despite their small size, double torsion springs can handle large amounts of torque. This makes them a preferred choice in applications where both power and compactness are required.

- Versatile and Adaptable: Double torsion springs are used across a broad spectrum of industries, from automotive and machinery to consumer products and aerospace. Their versatility ensures that they remain indispensable in various applications.

- Cost-Effective Performance: While delivering excellent performance, double torsion springs are cost-effective. They provide long-lasting value, making them an economical choice for a wide range of mechanical systems.

Conclusion

Double torsion springs continue to be a key component in mechanical design, helping to manage energy storage and torque in a wide array of applications. Whether in automotive systems, industrial machinery, or everyday products, their unique ability to efficiently store and release energy makes them a reliable solution. However, as technology evolves, will double torsion springs continue to hold their place, or will new innovations redefine how we manage rotational forces?

As we consider advancements in spring technology, could new materials or designs potentially outperform double torsion springs, or are they truly irreplaceable?

References:

- Journal of Mechanical Engineering: Torsion Springs and Their Applications, September 2021.

- The Evolution of Spring Technology in Industrial Applications, Industrial Design Review, June 2020.