The Rapid Development of the Spring Hardware Industry

Edit by chat.openai.com Launch by SHAW from Hengsheng Spring

Introduction

In recent years, the spring hardware industry has experienced remarkable growth and innovation, driven by technological advancements, changing consumer preferences, and the demand for efficient and reliable solutions across various sectors. This article delves into the key factors contributing to the development of the spring hardware industry and highlights the transformative impact it has had on modern engineering, manufacturing, and everyday life.

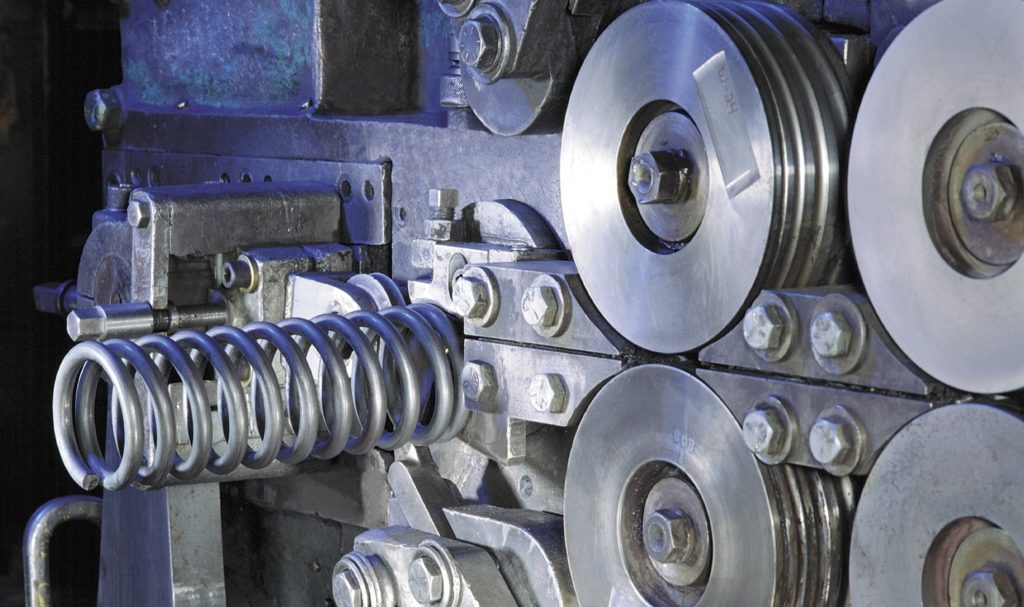

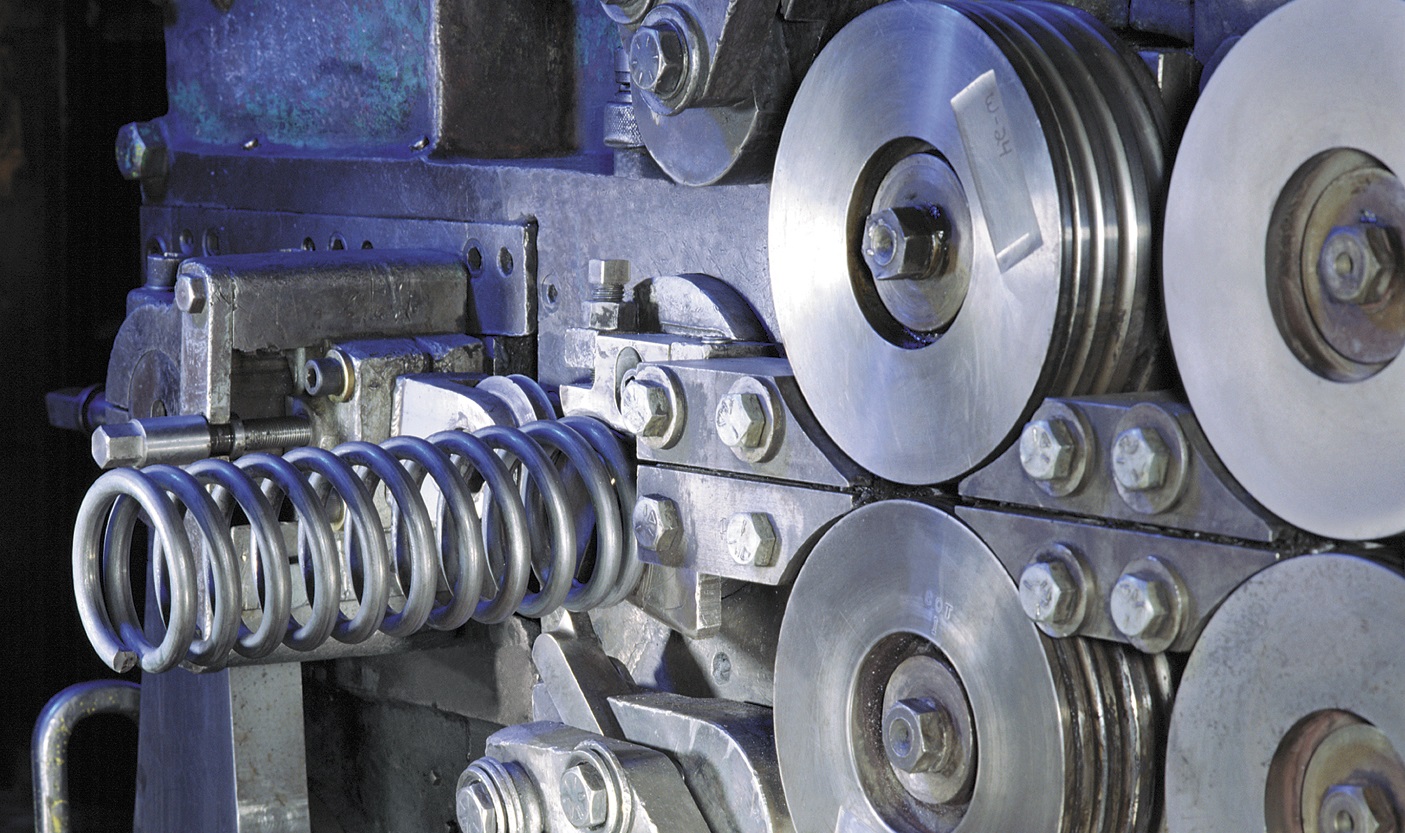

Technological Advancements and Material Innovations

One of the primary catalysts behind the growth of the spring hardware industry is the continuous evolution of materials and manufacturing technologies. Traditional steel springs are now being complemented and, in some cases, replaced by advanced materials like titanium alloys, composite materials, and shape memory alloys. These innovations offer enhanced durability, corrosion resistance, and flexibility, enabling spring hardware to perform effectively in diverse and demanding environments.

Furthermore, advancements in computer-aided design (CAD) and simulation tools have revolutionized the way springs are engineered. Engineers can now design intricate spring geometries, optimize load distribution, and predict performance accurately. As a result, this leads to more efficient and reliable spring hardware products.

Applications Across Industries

The spring hardware industry’s growth is not limited to a single sector; it spans across various industries.

Each sector benefits from tailored spring solutions:

- Automotive Industry: Springs play a crucial role in vehicle suspension systems, ensuring a smooth and stable ride. Recent developments have led to the creation of adaptive suspension systems that adjust in real-time based on road conditions. Consequently, this enhancement enhances both comfort and safety.

- Aerospace and Defense: Spring hardware is vital for aircraft landing gear, missile deployment mechanisms, and satellite systems. Furthermore, lightweight yet robust springs are now being used to reduce overall vehicle weight and increase fuel efficiency.

- Medical Devices: Miniaturized springs are at the heart of many medical devices, from insulin pumps to surgical instruments. Advances in biocompatible materials have expanded the possibilities for implantable medical devices and minimally invasive procedures.

- Electronics: The trend toward smaller and slimmer electronic devices has spurred the development of micro springs used in connectors, switches, and battery compartments. Consequently, this allows for more compact and efficient designs.

- Renewable Energy: Springs are integral to the functionality of wind turbines and solar panels. Moreover, developments in spring technology contribute to improved energy capture, storage, and conversion efficiency.

Sustainable Practices and Eco-Friendly Innovations

As sustainability becomes a paramount concern, the spring hardware industry is embracing eco-friendly practices. Manufacturers are exploring ways to reduce material waste, energy consumption, and environmental impact during the production process. Additionally, the industry is investigating the use of recycled materials and exploring bio-based alternatives to traditional metals, further contributing to a greener future.

Conclusion

In conclusion, the recent development of the spring hardware industry highlights its adaptability and resilience in the face of evolving technologies and consumer demands. From automotive engineering to medical advancements, springs have a ubiquitous presence. This presence is reshaping industries and improving the quality of products and services. Furthermore, as innovation continues to drive this industry forward, we can anticipate even more remarkable breakthroughs that will redefine the limits of spring hardware applications.