Aerospace

21 Years

Spring Manufacturer Experience

3000+㎡

Production Workshop

20+

Experienced Engineers

Unlimited

Custom Capabilities

About Aerospace springs

In the aerospace sector, particularly for space-based mechanical equipment, springs play a crucial role in ensuring the reliability and precision of various systems and components. Here are key areas where springs are utilized in space-exploration machinery:

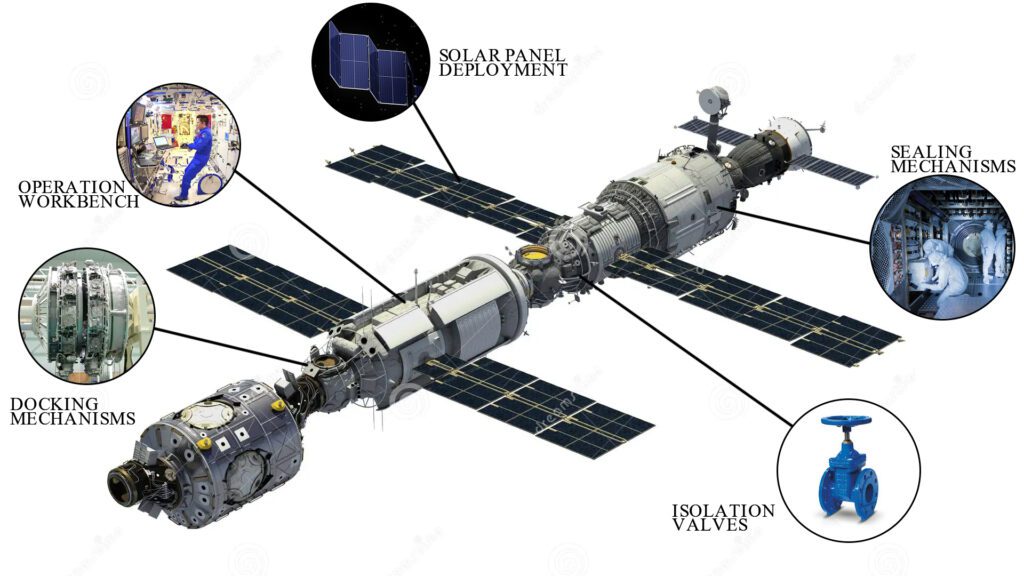

Satellite Deployment Systems:

- Solar Panel Deployment: Springs are used in the deployment mechanisms of satellite solar panels, ensuring that the panels unfold smoothly once the satellite reaches orbit and remain securely positioned to provide power.

- Antenna Deployment: Springs are integral to the deployment of communication antennas on satellites, ensuring proper positioning in space for effective signal transmission and reception.

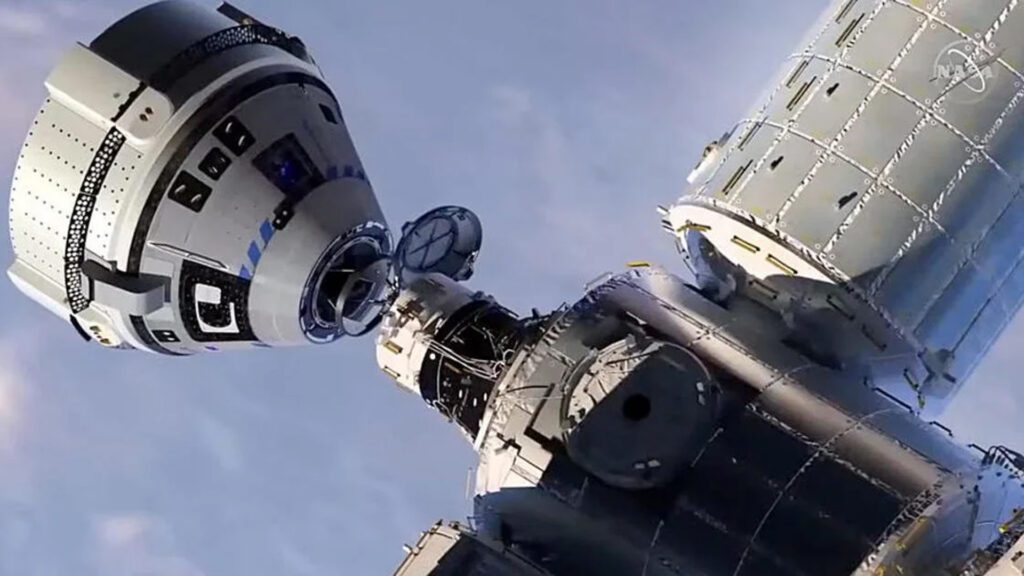

Spacecraft Docking Systems:

- Docking Mechanisms: Springs are employed in spacecraft docking systems to provide cushioning and secure locking during the docking process, ensuring a safe and stable connection between spacecraft.

- Separation Mechanisms: In multi-stage rockets and spacecraft, springs provide the necessary force for stage separation, ensuring that different sections of the spacecraft or rocket detach precisely at the designated times.

Attitude Control Systems:

- Gyroscopes and Reaction Wheels: Springs are used in gyroscopes and reaction wheels to fine-tune and stabilize the attitude control systems, ensuring accurate orientation and adjustments of the spacecraft in space.

- Thruster Control: Springs are part of the valve and flow control systems in thrusters, enabling precise adjustments to the spacecraft’s attitude and trajectory.

Landing and Ascent Equipment:

- Landing Shock Absorption: Springs are used in the landing gear of lunar modules and planetary landers to absorb the impact forces during touchdown, ensuring the safety of the equipment and instruments.

- Landing Gear: Springs are utilized in the landing gear systems of manned or unmanned spacecraft, providing necessary cushioning and support to ensure stability during takeoff and landing.

Extravehicular Activity (EVA) Equipment:

- Space Suits: Springs are incorporated into the joints of space suits, providing flexibility and elasticity to ensure astronauts can move freely while conducting spacewalks.

- Tools and Equipment: Springs are used in the clamping and deployment mechanisms of EVA tools, ensuring they can be effectively operated and securely stored in the space environment.

Scientific Instruments and Probes:

- Optical Instruments: Springs are used in the adjustment and stabilization systems of telescopes and optical sensors, ensuring precise positioning and stable observation in space.

- Sensor Deployment: Springs are integral to the deployment mechanisms of sensors and probes, ensuring they are correctly positioned and aligned for space-based measurements.

Sealing and Isolation Devices:

- Sealing Mechanisms: Springs are used in the sealing systems of hatches and experiment chambers to maintain airtight conditions and isolation in the space environment, preventing pressure loss or contamination.

- Isolation Valves: Springs are employed in fluid and gas control systems, ensuring valves can quickly and securely open or close to protect equipment and personnel.

Thermal Control Systems:

- Radiator Deployment: Springs are used in the deployment and adjustment systems of radiators to manage heat dissipation in spacecraft, maintaining optimal operating temperatures for onboard equipment.

- Thermal Expansion Management: Springs help manage the mechanical stress caused by thermal expansion, protecting the structural integrity of spacecraft components.

Propulsion Systems:

- Propellant Pumps and Valves: Springs are critical in the pumps and valves of propellant delivery systems, ensuring stable flow and precise control of propulsion in the vacuum of space.

- Ignition Systems: Springs are used in the ignition mechanisms of rocket engines and thrusters, providing precise force to ensure reliable engine start-up.

Structural Stability and Stress Relief:

- Vibration Dampening: Springs are used in vibration dampening systems for large space structures, absorbing and mitigating vibrations caused by spacecraft movement and external forces, thereby protecting sensitive instruments and equipment.

- Stress Relief Mechanisms: Springs are utilized to release accumulated stress in space structures, preventing damage due to thermal expansion or other environmental factors.

These applications demonstrate the essential role springs play in space exploration, particularly in ensuring the proper functioning and safety of mechanical equipment operating in the harsh environment of space.

Why choose Hengsheng Spring?

Quality

Strict Quality Control: Rigorous workflows ensure that every product meets or even exceeds customer expectations.

Certifications and Standards: Obtained relevant international and domestic quality certifications (ISO, CE, ROHS, etc.)

Price

Reasonable pricing strategy: Provide competitive prices by optimizing production and logistics costs.

Transparent pricing mechanism: Let customers clearly understand the composition and advantages of the price

Custom

Personalized customization: Provide customized products and services according to the specific needs of customers.

Quick response: Quickly handle customers’ customized needs and feedback to improve customer satisfaction.

R&D

Innovative products: Continuously launch new products to meet the changing needs of the market and customers.

Technical advantages: Possess independent intellectual property rights and patented technologies to enhance the technical content and added value of products

Manage

Stable supply chain: Ensure the stability of raw materials and production links and ensure timely delivery of products.

Efficient logistics system: By optimizing logistics channels, we ensure that products can be delivered to customers quickly and accurately.

Serve

Pre-sales service: Provide professional consultation and advice to help customers make wise

choices. After-sales service: Establish a complete after-sales service system to solve customer problems and needs in a timely manner

Brand

Brand building: Establish a good corporate image and market reputation through brand promotion and marketing activities.

Customer reputation: Win the trust and loyalty of customers through high-quality products and services.

Market

International market expansion: Actively explore international markets and expand brand influence and market share.

Localization services: Set up offices or partners in major markets to provide localized support and services.

EP&CSR

Green production: Use environmentally friendly materials and production processes to reduce environmental impact.

Social Responsibility: Actively fulfill social responsibilities, participate in public welfare activities, and enhance the corporate social image.

Progress

Customer feedback mechanism: Establish an effective customer feedback mechanism to continuously improve products and services.

Employee training: Improve employees’ professional capabilities and service levels through continuous employee training.

Contact Us

Need help with pricing or technical questions about custom springs? Or any other product-related assistance? Our team is equipped with sales professionals, design engineers, and manufacturing experts ready to address your needs. We’ll make sure you’re connected with the person most qualified to help.

Chat with Us

+86 18575541790

Email Us

shelly.wang@hengshengspring.com

Address

NO.12, Liandong U Valley , Yangxia Industrial Strict, Fuqing, Fuzhou, Fujian, China