onstant force springs deliver a nearly uniform force across their working range, making them distinct from traditional extension springs. Unlike conventional springs, which increase in force with extension, constant force springs offer a flat force profile. As a result, they suit applications that require consistent torque or controlled linear motion.

Structure and Operating Principle

Engineers manufacture constant force springs by tightly winding pre-hardened flat steel strips into coils. They often use materials such as 301 stainless steel, SK85, or Inconel to ensure strength, temperature resistance, and corrosion protection.

When you extend the spring, the internal residual stresses resist the motion and generate a constant restoring force. This effect occurs because the deformation distributes along the length of the strip, rather than concentrating in a single area. As a result, the spring behaves very differently from traditional coil springs.

If you attach the spring’s free end to a rotating spool or drum, it produces a constant torque, regardless of how many times you unwind or rewind the spring—provided it stays within its design range.

Mechanical Behavior

After uncoiling the spring to approximately 1.25 times its original inner diameter, it reaches its maximum rated load. Beyond this point, the spring exerts a nearly constant force throughout the remaining extension.

The output force depends on three main factors:

-

The thickness of the steel strip

-

The width of the strip

-

The mechanical properties of the material, such as yield strength and Young’s modulus

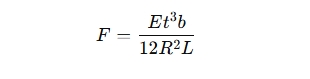

You can approximate the force using the following formula:

Where:

-

E = Young’s modulus

-

t = strip thickness

-

b = strip width

-

R = radius of curvature

-

L = developed length of the spring

Note: Although this formula gives a useful estimate, you should use experimental data or simulation for precise design.

Installation Guidelines

Proper installation ensures optimal spring performance and extends product life. Consider the following best practices:

1. Mounting on a Drum

To begin, wind the spring onto a drum or spool before installation. Make sure the drum diameter is 10–20% larger than the spring’s inner diameter to minimize stress and avoid coil damage.

2. Maintaining Free Turns

At full extension, keep at least 1.5 turns of the coil wrapped around the drum. Doing so prevents uncoiling beyond safe limits and maintains spring stability.

3. Avoiding Over-Extension and Reverse Winding

You should avoid stretching the spring too far, as over-extension can cause instability, twisting, or entanglement. In such cases, use guides and physical stops to maintain a controlled path of motion.

Moreover, never reverse wind the spring. Reversing the winding direction can induce harmful stress and potentially lead to early material fatigue or breakage.

Common Applications

Because of their unique behavior, constant force springs serve well in:

-

Counterbalance systems, such as copier scanner heads or flat-screen monitor arms

-

Cable and hose retractors

-

Window balance mechanisms

-

Motor brush tensioning

-

Medical devices like infusion pumps and surgical arms

According to a 2019 review published in Precision Engineering Journal, engineers prefer constant force springs in space-limited, high-cycle environments where traditional springs can’t provide stable output.

References

-

G.H. Boothroyd, Spring Design and Manufacture, Springer, 2005

-

ISO 2230:2020 – Storage of Springs – Guidelines

-

ASM Handbook, Volume 1 – Properties and Selection: Irons, Steels, and High-Performance Alloys

-

Precision Engineering, Elsevier, Vol. 57, 2019

-

Mubea Technical Handbook: Constant Force Spring Applications