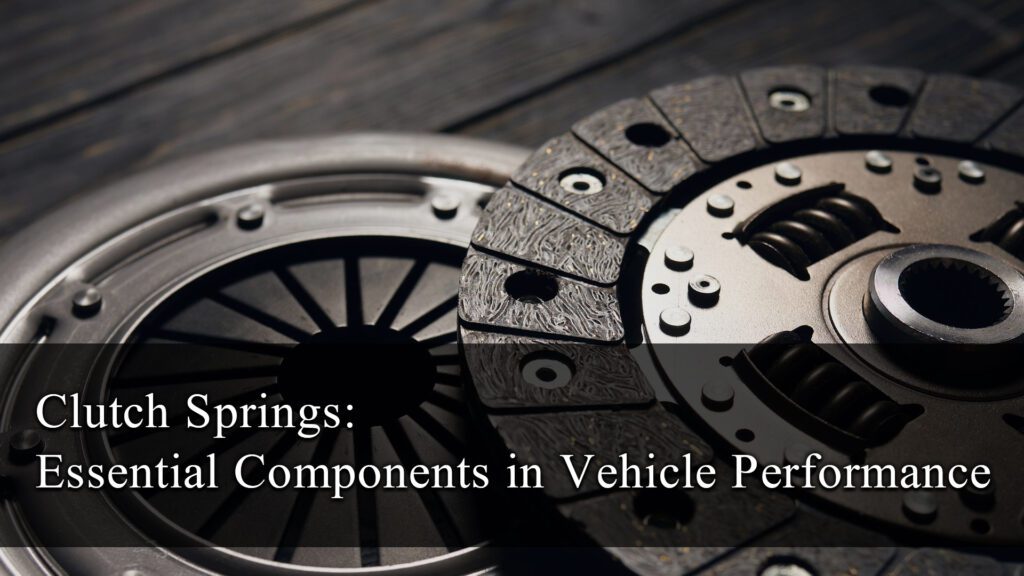

Clutch springs play a vital role in manual transmission systems, significantly impacting vehicle performance. By enabling smooth engagement and disengagement of the clutch, these components ensure a seamless driving experience.

1. Introduction to Clutch Springs

Clutch springs, typically crafted from high-strength steel or other durable materials, maintain the necessary tension for effective clutch operation. They allow the clutch plate to engage and disengage smoothly, which helps drivers change gears effortlessly. These springs endure significant stress as they compress and expand during normal driving.

2. Applications and Roles of Clutch Springs

Clutch springs primarily function in vehicles with manual transmissions, but they also find applications in various machinery that requires controlled engagement of rotating parts.

Automotive Applications:

- Manual Transmissions: In cars with manual gearboxes, clutch springs provide the force needed to disengage the clutch when the driver presses the pedal. This action allows for smooth gear changes without grinding or damaging the transmission.

- Performance Vehicles: High-performance cars often use specialized clutch springs designed to handle increased power and torque. These springs can be tuned for different driving styles, ensuring optimal performance under various conditions.

Industrial Equipment: Clutch springs also appear in industrial machinery where torque transfer is necessary. For example, they help engage and disengage gears in conveyor systems and other heavy machinery.

3. Advantages and Unique Features of Clutch Springs

Clutch springs offer several advantages that make them indispensable in both vehicle and machinery performance:

Durability:

Manufacturers construct clutch springs from high-quality materials, allowing them to withstand the wear and tear associated with repeated use. Their robust design ensures longevity, which is essential for maintaining vehicle performance over time.

Precision Engineering:

Engineers design clutch springs to provide the exact tension required for smooth engagement and disengagement. This precision minimizes the risk of clutch slippage or premature wear, contributing to overall vehicle reliability.

Customization:

Many manufacturers offer clutch springs that can be customized to meet specific performance needs. For instance, racing applications might require stiffer springs to handle higher power outputs, while everyday vehicles benefit from standard tension springs for smooth operation.

4. Conclusion: The Unsung Heroes of Vehicle Performance

Clutch springs serve as critical yet often overlooked components in the automotive and industrial sectors. Their ability to provide precise control in clutch engagement directly influences vehicle performance and user experience. As technology continues to advance, the demand for more efficient and durable clutch springs will likely increase.

But as vehicle performance evolves, will clutch springs keep pace, or will emerging technologies redefine our understanding of clutch engagement?

References:

- Automotive Engineering Journal, “The Role of Clutch Springs in Manual Transmission Systems,” Volume 29, Issue 4, 2022.

- Industrial Machinery Review, “Durability and Performance: The Importance of Quality Clutch Springs,” Volume 18, Issue 2, 2023.