Exploring Spring Structure: Inner Diameter, External Diameter, Coils, Pitch, Wire Diameter, and Hengsheng Spring‘s Expertise

Springs, essential mechanical components, are found in numerous applications, from household items to industrial machinery. Understanding spring structure, including inner diameter (ID), external diameter (OD), coils, pitch, and wire diameter, is crucial for designing or selecting springs that meet specific performance requirements. In this article, we’ll delve into these key elements. Additionally, we’ll highlight Hengsheng Spring’s manufacturing expertise.

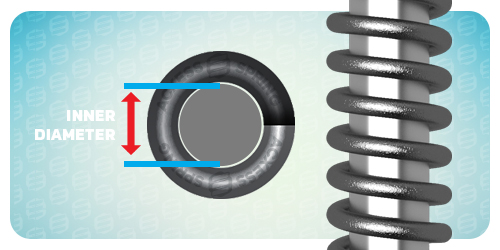

Inner Diameter (ID)

Firstly, let’s discuss the inner diameter (ID), which defines the space within the coiled wire. Smaller IDs result in tighter coils, yielding stiffer springs. Conversely, larger IDs create softer, more flexible springs. Engineers carefully choose IDs based on specific performance needs.

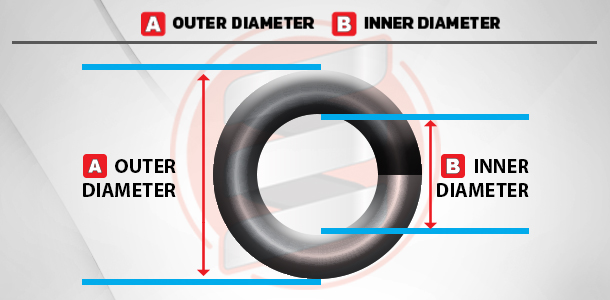

External Diameter (OD)

Moving on to the external diameter (OD), this parameter encompasses the spring’s size, including wire thickness. It significantly impacts strength, stability, and fit within assemblies. When designing a spring, considering the OD is crucial to meet space constraints and load-bearing requirements.

Coils

Now, let’s examine the coils themselves. Coils are the helical windings of wire forming the spring body. The number of coils plays a pivotal role. More coils lead to longer, softer springs, whereas fewer coils result in shorter, stiffer springs. The coil count directly determines whether the spring functions primarily for compression or extension applications.

Pitch

Next, we delve into pitch—the measurement of the distance between adjacent coils. Shorter pitches yield tighter helices, making springs stiffer. On the other hand, longer pitches produce more open helices, resulting in softer springs. Engineers consider pitch crucial for tailoring springs to meet specific requirements.

Wire Diameter

Turning our attention to wire diameter, also known as gauge, this parameter significantly impacts the spring’s strength and load-carrying capacity. Thicker wire translates to stronger springs capable of withstanding higher loads. Conversely, thinner wire yields more flexible and lightweight springs.

Hengsheng Spring’s Manufacturing Expertise

Finally, let’s highlight Hengsheng Spring’s exceptional manufacturing expertise. This renowned manufacturer excels in producing high-quality springs. With advanced facilities and experienced engineers, Hengsheng Spring has the capability to create customized springs while adhering to stringent quality standards.

Hengsheng Spring collaborates closely with customers to design and manufacture springs for diverse applications. Their unwavering commitment to innovation ensures precision and consistency in every spring produced.

Conclusion

In conclusion, comprehending spring structure, including parameters like ID, OD, coils, pitch, and wire diameter, is vital for designing or selecting springs that meet specific performance requirements. Hengsheng Spring’s manufacturing expertise adds a valuable dimension to the world of spring production, offering tailored solutions that meet the highest standards of quality and precision.