About Extension Springs

Because extension springs are a type of mechanical spring used to resist axial forces and extend under load. Therefore, they are typically made of high-carbon steel, stainless steel, or brass and come in various sizes and shapes depending on the application.

Because of their durable material, extension springs are commonly used to restore force to components that extend or pull apart. In fact, when compressed, they absorb and release the stored energy as the spring returns to its original position when removing the load.

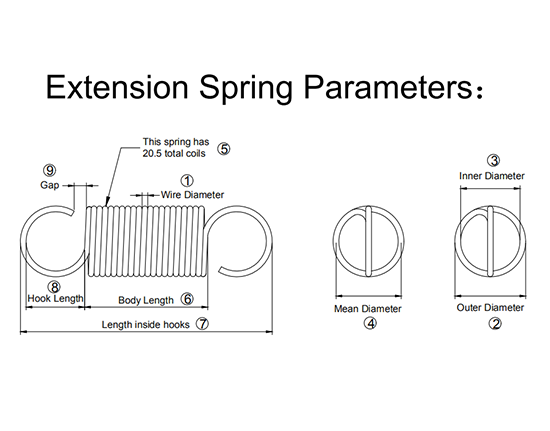

Additionally, the performance of extension springs depends on various factors, for example, the wire size, number of coils, and the tension applied. Additionally, the wire size and number of coils determine the spring’s strength, while the tension applied determines how far the spring can stretch before it reaches its limit.

Furthermore, producers commonly use extension springs in various applications, including garage doors, exercise equipment, screen doors, and industrial machinery. As a result, they must be designed with proper tension to ensure they perform as intended and have a long lifespan. Therefore, regular inspection and maintenance are needed to help to ensure the extension spring continue to function properly over time.

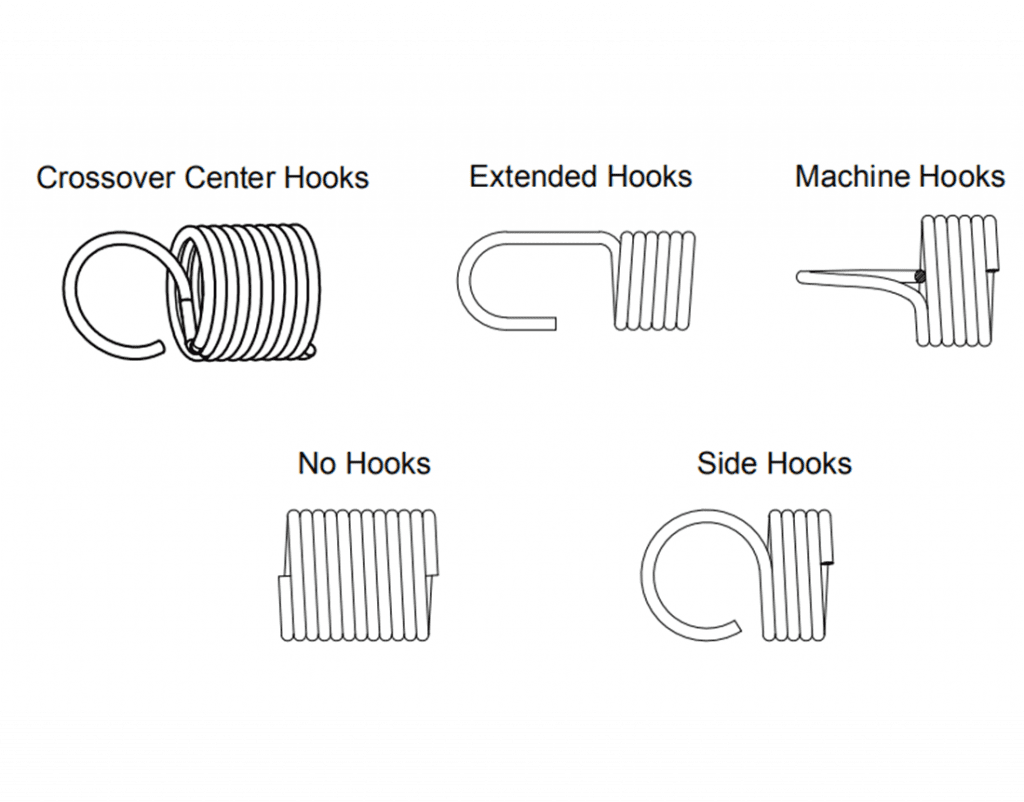

Hook type of extension spring

In addition, you can choose from many different hook types of extension springs, such as crossover center hook, extended hook, Machine hook, side hook, and more.

Material and Finish

- Carbon Steel: 65 Mn, 72 A, 82 B, SWP, Galvanized wire, Nickel-coated wire

- Stainless Steel: SS 201, SS 302, SS 304,SS 316,SS 631

- Copper Base Alloy: Beryllium Copper Springs, Phosphor bronze, Brass spring, Tin bronze, Silicon bronze

- Alloy Steel: 60Si2Mn, 55CrV, 55CrSi

- Surface treatment: Zinc, Nickel, Copper, Gold/Silver, Chrome-plated, Black oxide, Electrophoresis