About wire forming springs

Wire-forming springs, also known as wire-formed springs, are mechanical devices made from a single piece of wire bent and shaped into a spring. Moreover, the automotive and computer industry widely use wire-form springs in various industries and applications, including automotive, medical, industrial, and consumer products.

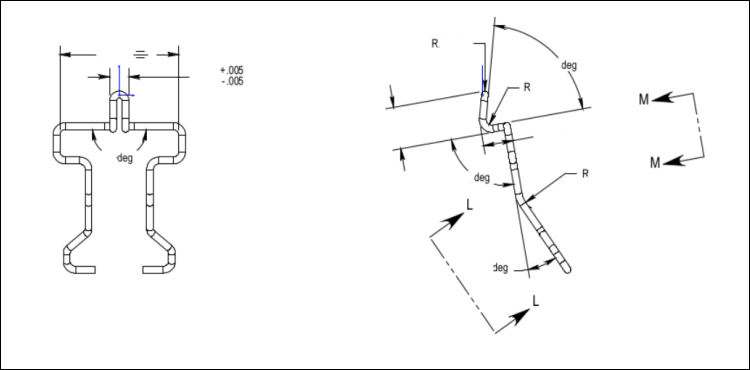

The manufacturing process of wire-forming springs involves using specialized machinery to form the wire into the desired shape. This process can include bending, twisting, and shaping the wire into intricate designs that meet the application’s specific requirements. Different forming techniques, such as cold forming, hot forming, and stamping, can achieve the desired shape and properties of the wire-formed springs.

The material used to make wire-forming springs can vary depending on the application and requirements. Common materials include high-carbon steel, stainless steel, and various alloys. Therefore, the choice of material depends on factors such as the required strength, operating temperature, and corrosion resistance. The supplier will sometimes apply surface treatments, such as plating or coating, to enhance the wire-formed springs’ performance and durability.

Moreover, designing and manufacturing wire-forming springs require precision and expertise to meet the application’s requirements and provide long-lasting performance. For instance, manufacturers must carefully consider different factors such as the wire diameter, number of coils, and spring rate during the design process to ensure the proper functioning and reliability of the springs. Computer-aided design (CAD) and simulation tools can optimize the wire-formed springs’ design and performance.

Furthermore, regular inspection and maintenance are also essential to ensure the wire-forming springs continue to function correctly over time. In addition, proper handling, storage, and installation of the springs can help to prevent damage and prolong their lifespan.

Material and Finish

- Carbon Steel: 65 Mn,72 A,82 B, SWP, Galvanized wire, Nickel-coated wire

- Stainless Steel: SS 201, SS 302, SS 304, SS 316, SS 631

- Copper Base Alloy: Beryllium Copper Springs,Phosphor bronze ,Brass spring,Tin bronze,Silicon bronze

- Alloy Steel: 60Si2Mn, 55CrV, 55CrSi

- Surface treatment: Zinc, Nickel, Copper, Gold/Silver, Chromeplated, Black oxide, Electrophoresis